Top ranking of the best tile cutters in 2019

Today it is impossible to imagine the construction of various houses, summer cottages, saunas, office buildings or building complexes without the use of modern tiles, which are very important for decoration. There are many types of tiles, including marble or ceramic and porcelain stoneware. Therefore, it is useful to have a great tool on hand - a tile cutter. We will tell you about the best models for 2019 in this article.

Attention! A more up-to-date ranking of 2020 of the best tile cutters is compiled in separate material.

About tile cutters, safety at work and stone processing

For the work of the tiler and the tiler, a tile cutter is used, that is, a special tool for cutting tiles, stone, and also glass. Cutting is done in many ways:

- the imposition of risks, an incision, and breaking of the material is already done along it;

- cutting and sawing;

- biting off pieces from the edge.

Whatever the facing is, everywhere it is required to make undercuts to the required dimensions and straight cuts, as well as holes, indentations and curly cuts, 45 degree cuts. These special steps depend on the type of product. Not every tile cutter has all the functions, and it is advisable to take this into account when purchasing a structure.

There are three main types of device:

- mechanical;

- electric;

- manual.

When using electric tile cutters, it must be borne in mind that they cannot tolerate humidity more than 70%. The product is placed only on a flat floor, and if it is a large-sized machine, then a separate room is allocated for work. They use glasses, special headphones, since abrasive dust collects in the air, and the noise level is up to 85 dB. It is better not to overload the mechanism. When thick tiles are cut and the material is fed too quickly, it is dangerous. There is a risk of overheating of the engine and the possibility of splitting the equipment.

How to choose a product

To buy a mechanical tile cutter, it is wiser not to pursue a low price in order to save money. The cost of the goods varies from 300 to 2500 rubles. Cheap models under 1000 rubles are good only if they are rarely used for ceramic soft tiles. More expensive models with a price of 1000-2500 rubles are suitable for long-term operation, as they can withstand enormous loads during operation.

Models up to 6,000 rubles are suitable for domestic use. The cheapest samples are suitable for frequent cutting of glass, porcelain stoneware or ceramics, but they are not used for cutting stone. The device up to 30,000 rubles is professional, it is easy and convenient for them to perform accurate cuts and work with hard materials. Ordinary cheap specimens can be used in modern professional construction, for working with slabs of stone or concrete with a thickness of more than 100 mm.

The cost depends on the brand. The most inexpensive models: Bison and Caliber, Enkor, Energomash. The world famous companies DeWALT, Fubag, Bosch, Stayer produce more expensive devices.Manufacturers usually give warranties for 1-2 years on their equipment, and also provide warranty repairs. When carrying out repair work in the kitchen and in the bathroom, where tiles are up to 15 mm thick, a mechanical tool is used. If the thickness of the material reaches more than 30 mm, then an electrical structure is required.

Product selection criteria

Please pay attention to the dimensions before purchasing the product. A small frame 400x180 mm is suitable for cutting ordinary tiles. In this case, the strength of the bed material is taken into account, the durability depends on it.

For frequent work, a circular cutter, special built-in squares, rulers, tile strengthening mechanisms are important. Use an electric tile cutter when cutting hard, thick ceramics or trimming.

The speed of rotation of the disk is of great importance, therefore protection from flying fragments of ceramics and enamel is required. The idle speed does not matter. The motor power is very important and should be 2 kW on average. The diameter of the common cutting blade depends on the working power of the product. The larger the blade, the thicker the material is cut. When fitted with a 350mm blade, it easily cuts 135mm material.

The main selection criteria: the popularity of models, characteristics. Manufacturers and cost are taken into account.

Top ranking of the best tile cutters

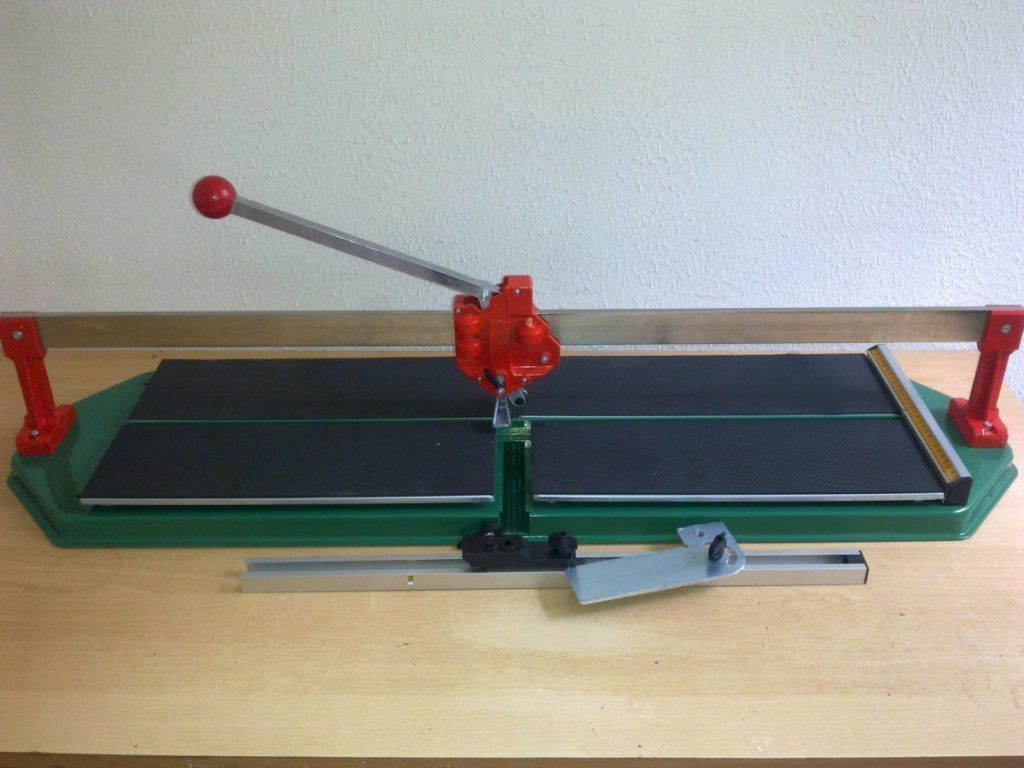

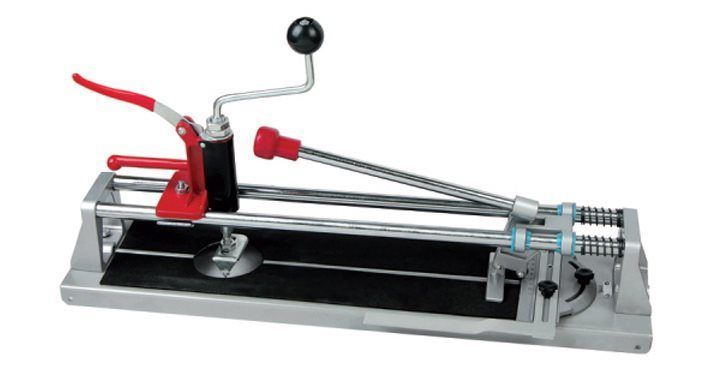

Mechanical devices

Nuova Battipav SUPER PRO 900

The modern and special Nuova-Battipav SUPER PRO 900 is an excellent tile cutter for diagonal, straight cutting of double or single fired ceramics. Perfectly cuts stoneware products. The carriage consists of nine ball bearings, quick and easy adjustment. This product cuts tiles from itself. The work table is equipped with springs to facilitate breaking of 5-19 mm thick cut tiles. A large cutting wheel with a diameter of 22 mm, there is a graduated special stop for a straight cut, and the tile itself will be easily broken at the cutting point.

Manufactured by an Italian company. It is used for cutting material up to 900 mm long, as well as for diagonal cutting of 63x63 tiles. The cutting accuracy is perfect, the break is excellent, suitable for construction repair work. The dimensions of this design are traditional. The machine is excellent, professional.

Specifications:

- the product has a professional class, manual type;

- goes with a broach;

- table dimensions 636x636 mm;

- the dimensions of the knife are 22x6.1x4.7 mm;

- tilt angle up to 45 degrees;

- there is no drilling device;

- sliding bearing mechanism;

- 1 year warranty;

- dimensions 1160х340х160 mm.

Video review of the device:

- the quality of the model is excellent;

- easily cuts tiles 60x60;

- there will be no leads for sure;

- weak chips;

- comfortable design;

- assembly;

- high cutting accuracy;

- compactness;

- ease of transportation.

- overall performance is weak;

- cost

- uncomfortable handle.

Bottom line: Handmade excellent quality tile cutter has a working surface of 900 mm, easily copes with cutting tiles. The design is robust. The average cost is 2,000 rubles.

SIGMA TECNICA 2A3

Has a compact small size. The model is functional and durable. The cutting system is standard. The device allows you to cut various materials with great thickness. The pull-type cutting system makes it possible to process materials quickly and easily. Differs in such qualities as accuracy, speed, great cutting precision. The cutting length goes exactly to 51 cm, the cutting diagonal is 35 cm by 35 cm with a cutting depth of 20 mm.

The work table reduces the cutting rigidity and also creates a shock absorption effect. When the tiles are split, the precision ruler is centered. Has a locking system at every angle. For speed of movement, it is fixed to the platform along the rail of the product. The tool is compact, easy to use.

Specifications:

- the working table is 28 cm wide;

- cutting with a conventional system;

- cutting wheel 12 mm;

- table with springs;

- there is a cut of 45 degrees;

- 5 years warranty.

- the ruler is close to the tiler, which is very convenient;

- ball bearings provide easy sliding of the spacer;

- spring-loaded table, which is effective in separating material;

- you can buy more rollers for cutting glass, enamel and glazed tiles and mosaics;

- cuts thick materials.

- cost;

- the handle is not the most comfortable;

- there are chips.

Bottom line: The modern tile cutter cuts thick material. A convenient ruler is available. The table is excellent. The average price is 14,500 rubles.

Favorit 11-225

It is an excellent modern pliktorez. Works on bearings, has a long service life. Bed width - 180 mm. Serves for cutting different tiles up to 16 mm thick. The stop bar can be easily rotated up to 90 degrees, there is a spare cutting element. The cutter length is 500 mm and the diameter is 22 mm. Uses a special top feed of the cutter and blade when cutting ceramic floor tiles. The bed is equipped with reinforced ribs made of special steel.

Specifications:

- type of construction of the manual type;

- Mechanics;

- manufacturer China;

- transverse cut at 45 and 90 degrees;

- there is an element for adjustment;

- used by experienced builders.

- efficient tile cutter;

- hand-held convenient device;

- used for different ceramic tiles;

- year warranty;

- cuts great.

- the angle of the roller.

Bottom line: Favorit is used for cutting ceramic tiles. The average price is 30,000 rubles. When buying a tile cutter, consider the company's reputation.

Electrical devices

Husqvarna TS 66 R

It is boldly called a professional product. There is a special and convenient pump. The working standard saw moves clearly along the rail, the cut is easily controlled. The only drawback is the lack of a ruler that can be installed independently. Expensive mechanism. An ideal tool for experienced builders. Long service life. The cut is easily adjusted, the cutting tool maneuvers. Powerful motor performance.

The cutting depth is standard and equal to 40 mm. Differs in workmanship. According to numerous reviews, the cut is accurate, and the error is 0.3 mm. The electric work table is wide and easily cuts different sized tiles. The special type disc has a diameter of 200 mm. The design is simple, the cutting head allows you to cut various materials. The stroke is great and the kit is normal.

Specifications:

- source of work - network;

- cut at 90 degrees;

- protection class IP 54;

- minimum sound pressure level;

- noise has a level of 63 dB;

- frequency 50 Hz.

Tile cutter video review:

- ideal technical properties;

- convenient feeding system;

- there is a collection of water;

- adjustable carriage;

- cool machine;

- convenience of work;

- understands quickly.

- the table quickly rusts;

- expensive.

Bottom line: Product dimensions are large, cutting accuracy is excellent. Used for stone, tiles, porcelain stoneware and marble, as well as cutting bricks. The average price is 30,000 rubles.

Fubag MasterLine 6 Star 660

Electric machine for cutting stone and tiles, performs corner and straight, as well as combined cuts, thanks to the cooling system, it works for a long time. It is supplied with a special cooling system that prolongs the life of the machine. The table is large, it processes large stones.

For work, it is better to use a cutting depth of up to 30 mm. The frame has 8 stiffeners. In the presence of a tray for water. The tool provides cutting time. Equipped with a fan to cool the working motor. It works intensively and stands out for its precision and cut quality. The structure is easily disassembled, convenient in storage and transportation. The maximum cutting length is 660 mm.

Specifications:

- cutting depth 50 mm;

- way top;

- revolutions 2800;

- cutting angle 90 ... 45;

- 0.8 kW motor;

- works from a 220 V network;

- dimensions are compact;

- weight 30 kg;

- material - ceramics and stone;

- disc diameter 200 mm;

- cut angular, accurate.

Video review of the tool:

- clear apparatus;

- quality assembly;

- saving time due to the quality of the cut;

- parts of the body are connected securely;

- tight and precise carriage travel;

- the disc is easily lowered and raised comfortably;

- works great.

- the location of the crane is strange, that is, above the motor;

- flexible wiring is not perfect;

- if the maximum cut is made, then it is convex, and not clear;

- there is no fixation for the tile;

- original disc of low quality;

- sometimes the disc beats.

Bottom line: The electric machine makes corner and straight cuts, the cutting accuracy is significant, and thanks to the cooling system, the machine works for a long time. The average price is 30,000 rubles.

DeWALT D24000

Serves for wet cutting of concrete, stone, porcelain and brick, ceramics. Provides a variety of cuts: straight, diagonal, and sloped. Working cutting accuracy is maximum. The cantilever system will provide a working width of up to 610 mm, requires special grounding. The design has a special water collector at the back, moves with the table and catches water that comes from a large tile when diagonally cut.

The cutting disc is fitted with a minimum diameter of 150 mm. The dimensions of the disc are up to 254 mm. In the presence of the ability to cut with an angle of 22.5, 45, 90 degrees. For easy fast transportation, dismantled parts should be placed in a special bath, and for easy cleaning of the structure, there is a removable cutting trolley.

The machine is used in domestic conditions, for modern workshops, granite workshops. It features a more powerful motor, a large disc, and is powered by three-phase current. For safety, a stop button with a lock is equipped.

Specifications:

- power 1600 W;

- the number of revolutions 4200 per minute;

- acoustic power 103 dB;

- standard equipment;

- cutting depth up to 95 mm;

- made in the USA, assembled in Taiwan;

- year warranty.

More about the tool in the video:

- i> thanks to the rubber slide, different tiles are rigid;

- the cleanliness of cutting even fragile material is excellent;

- there are oblique cutting, rosette, gutters;

- the assembly is excellent;

- the model serves for a long time;

- no rusting;

- cutting depth 95 mm.

- the saddle is not flat;

- the engine may roar violently when starting and running;

- it's expensive;

- the original disc is easily erased;

- difficulties with the format.

Bottom line: Serves as a machine for wet special cutting of materials, provides a variety of work. The average price is 60,000 rubles.

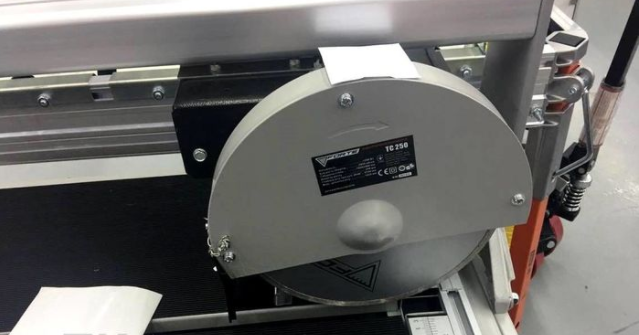

Forte TC 250

The Forte TC 250 cutting design is suitable for mobile stationary work because of its small size and convenience. It has a range of possibilities, an excellent tool, the cutting depth here is greater than that of other products. There is a durable copper-wound motor, which is required to increase the service life and great functionality, the cut will be accurate in tiles and stones.

The product is excellent and cuts various materials. Suitable for a specialized workshop. The stroke length is 1.02 meters. The machine is compatible with discs up to 25 cm. Equipped with a powerful motor. Cuts almost all types of tiles. There is a water supply for work.

Specifications:

- power 1200 W;

- product type electrical;

- large table;

- sold in a special cardboard box;

- cutting depth - 50 mm.

Tool overview - in the video:

- quality product;

- cuts ceramics and marble;

- price;

- perfectly cuts and makes holes;

- high number of revolutions;

- cooling.

- the disc, if you press very sharply against the tile, it slows down;

- table without rubber.

Bottom line: Easily and quickly processes the material, suitable for all types of tiles. The average price is 15,000-16,000 rubles.

FUBAG A-100 KM

The machine is powerful. The stone cutter is used for universal use, copes with the processing of artificial and mineral materials. For each texture - a special disc, which is covered with a steel protective casing. Cuts many products from stone to concrete up to 1000 mm in length. The table has a unique structure with a frame.The modification has an electric motor 220 V.

Specifications:

- type of product diamond work;

- desktop type construction;

- cutting depth up to 110 mm;

- the cutting angle is permissible, 45-90 degrees;

- weight 108 kg;

- front-feed disc;

- power 2.2 kW.

- functional;

- handles well;

- cutting depth is excellent;

- number of revolutions 2800;

- cut quality.

- The engine should be even more powerful;

- overpriced;

- processing is slow.

Bottom line: Great for all types of material from ceramics and concrete to stone with a length of 1000 mm. The design of the table is ideal, the rigidity is large, there is cutting with a processing angle. The average price is 130,000 rubles.

Sakuma TS180S3

Sakuma TS180S3 is an electric stationary machine that consumes 800 watts. Dry cut is available. Power is supplied through a 230 V network. Manufacturer - Sakuma, China. The diameter of the diamond disc is 180 mm. The table is comfortable. Product warranty - 1 year.

The machine is used for conventional cutting of modern medium and small tiles for walls and floors. Galvanized working table.

Specifications:

- cooling;

- table with minimal dimensions;

- the number of revolutions is 2950;

- corner cutting 45 degrees;

- angular emphasis.

- sufficient power;

- convenient operation button;

- cuts ceramics;

- there is wet cutting.

- the table is weak;

- overall handle is terrible.

Bottom line: A standard design with a power of up to 800 W operates from the mains. The average cost is 3000 rubles.

About the tool

Today, tiles have become the most fashionable material for which you need to buy a tile cutter. Its type and appearance depends on the quality of the texture. It will allow processing both glass and stone. Differs in ease of use and efficiency in work.

In the presence of a wide range of tools. It will not be difficult to choose the required model based on the functionality, scope of work and cost.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive medicines for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85092 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72463 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296