Rating of the best self-priming pumps for industrial needs for 2020

Some types of self-priming pumps can be used not only in household, but also used on a large scale for industrial needs. Such devices are capable of pumping large volumes of special fluids, which may vary in composition and consistency. Such industrial pumps are subdivided into peristaltic (they are also hose), screw and gear.

Hose pumps

Hose or peristaltic pumps refer to special devices that imply the principle of volumetric action, which consists in pumping liquids by forcing them through a pipeline, which is a flow path of pumping equipment. The design of these devices includes an elastic hose and several rollers, due to the rotation of which a pressing effect on the liquid substance is carried out to the track, as a result of which the flow area is narrowed. Thanks to this technology, the liquid flows through the hose at a high flow rate.

The main advantages of such devices are:

- Increased tightness;

- The metal parts of the device are absolutely not in contact with the pumped substance (additional level of protection);

- The equipment is quite simple to repair and maintain;

- It is possible to dose abrasive / aggressive / viscous liquids;

- Self-priming function;

- During operation, a reduced noise regime is observed.

These properties suggest a fairly wide scope of use of the equipment under consideration. It is successfully used in the pharmaceutical and chemical industry, food industry, laboratory and medical research, agriculture, construction and most other industries.

The devices have proven themselves to be excellent in solving water and wastewater treatment issues. At the same time, during the production of these works, it is possible to dose chemical reagents for water treatment, for example, activated carbon, lime, ferric chloride, sodium hypochlorite, etc. They can also ensure the movement of sludge and the supply of products to the filter press.

To do this, they have significant advantages:

- Lime and other substances with abrasive properties can quickly wear out pumps of other types (for example, screw and diaphragm);

- Most polymers are supersensitive to various shears, and hose equipment allows pumping without destruction of their structure;

- Sludge can contain most of the impurities (coarse), which may well cause damage to the internal structural elements of other types of pumping equipment.

Another large-scale use of peristaltic pumps is the chemical industry. There, such pumps make it possible to pump alkalis and acids, chalk and aluminum alum solutions, and also with their help they drain wastewater containing large foreign particles. There is also a separate category of peristaltic pumps that can pump radioactive liquids - they are used at nuclear power plants. But the best peristaltic equipment has proven itself in the general construction sector, where it is used to supply mixtures, viscous paints, and various adhesives. And instead of the procedure for cleaning the pump pipeline from sticky joints after carrying out the above operations, you can easily carry out the usual pumping out of water with a small degree of contamination.

Screw pumps

They are also called eccentric screw pumps. They are volumetric equipment.

The main areas of application are:

- Food industry (pumping sugar syrup);

- Oil industry (pumping drainage water from wells);

- General construction works (pumping high-viscosity liquids containing solid foreign bodies).

- The performance of the above types of work became possible due to the application of the principle of fluid movement in the screw pump due to the injection of high pressure areas.

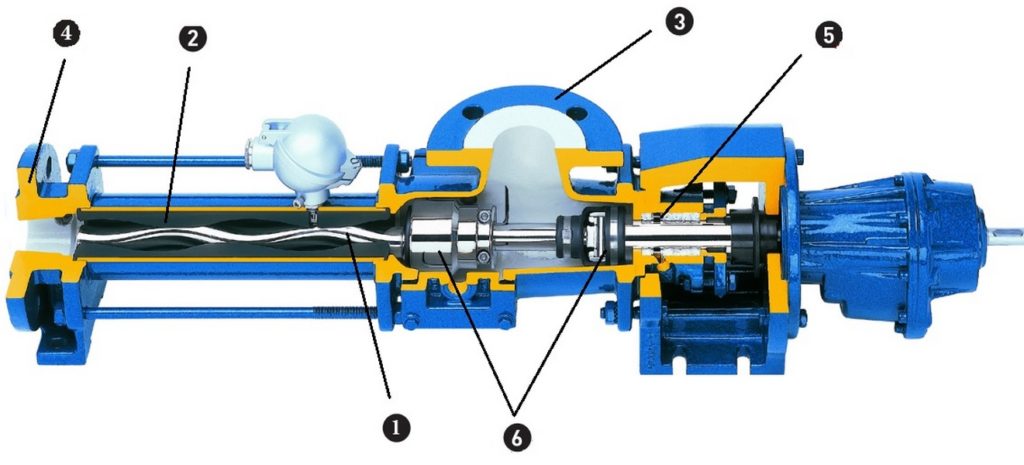

Screw pump: device and design

The heart of such equipment is a spiral metal rotor that rotates in an elastomer stator.

The screw pump consists of:

- Rotor;

- Stator;

- Suction pipe;

- Sealed shaft;

- Cardan joints.

The action of such a pump is as follows: the rotor, which is tightly attached to the elastomer stator, forms a double chain of fully sealed compartments. During the rotation of the rotor, the distilled liquid fills these compartments and gradually passes from the suction pipe to the discharge pipe, while neither the shape nor the volume of the liquid in the compartment changes.

Most models of screw pumping equipment have a pumping capacity from 100 cubic meters / hour to 500 cubic meters / hour. Depending on the working volumes, the pressure can be maintained from 6.1 to 49 atmospheres. The number of steps can vary from 1 to 8 pieces. The viscosity of the pumped liquid can be from 2 to 3 million cps. The maximum size of foreign matter in the pumped substance must not exceed 150 mm.

The advantages of screw pumps are:

- Possibility of pumping high viscosity liquids;

- Ensuring work by injecting high pressure areas;

- Possibilities of continuous supply of liquid for pumping;

- Self-priming;

- A wide range of substances that can be pumped;

- Work with liquids with large foreign inclusions.

The disadvantages of screw pumps include:

- Excessively large dimensions (the more steps such equipment has, the longer its flow path becomes);

- It is extremely difficult to maintain (it is unlikely that it will be possible to replace a failed element on its own, not only special knowledge, but also special equipment will be needed);

- Very high price for spare parts;

- Due to the fact that the stator and rotor are in constant contact, this circumstance leads to their rapid wear;

- Dry running is strictly prohibited (equipment breaks down instantly).

However, it should be noted that screw pumps have a wide range of applications. They can be used for pumping multiphase liquids, pumping crude (heavy) oil, pumping highly viscous substances (resin, tar, bitumen, rubber).Low-stage models can be used in the food industry, and to support construction work, they can pump glue and paints and varnishes.

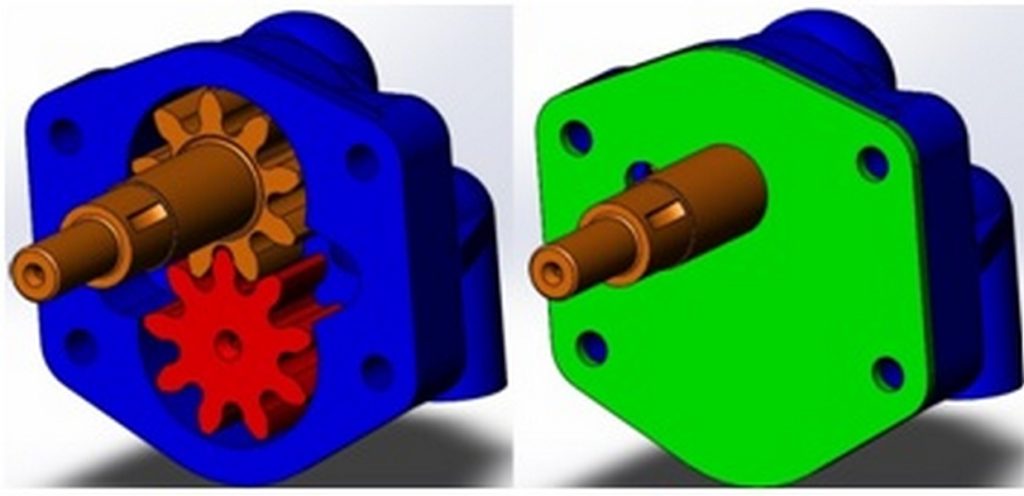

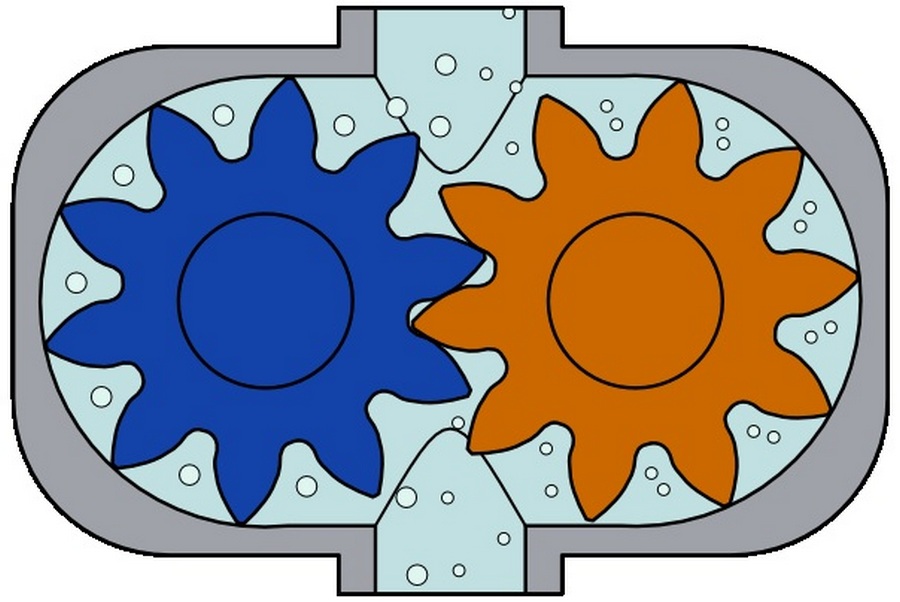

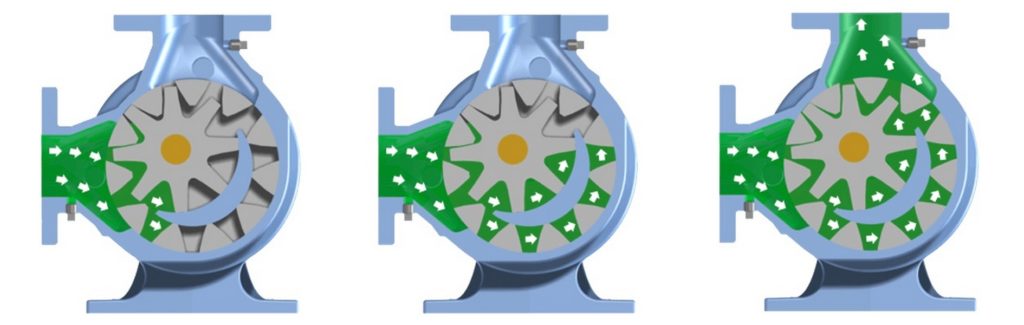

Gear pumps

This is the name given to gear pumps that operate on the positive displacement principle. They move the liquid substance repeatedly overlapping its fixed volume by means of blocking teeth (gear wheels), while the movement is carried out according to the principle of a cyclic pump. This process provides a pulse-free flow that is directly proportional to the speed of rotation of the gear.

Operating principle

The basis of gear pumping equipment is that a rotating element creates a liquid seal in the housing. The substance that the pump has drawn in is instantly contained in the gear compartments, which transfer it to the drain. Gear pumps can have both internal and external gearing.

- External gear

Such a pump consists of two equivalent gears that block each other, while being simultaneously supported by two different shafts. The gears are interconnected and one drives the other. The liquid flows into the compartments and is captured by the teeth, after which it is distilled from the suction pipe to the drain around the casing. At that moment, when the teeth of the wheels touch on the pressure side, then this leads to a decrease in volume, and the liquid substance begins to be displaced due to the resulting pressure. In the opposite direction, the liquid cannot return under any circumstances, because the teeth have already touched and are in a locked position. The tight tolerances between the housing and the gears allow this type of equipment to increase the suction at the inlet and prevent any leakage on the discharge side.

Both herringbone and cylindrical gears can be used on external gear units.

- Internal gearing

The principle of operation of such pumping is a bit similar to that described above, with the only difference that it uses gears of different levels. The rotor is a large gear, inside which a small gear is inserted. Moreover, the last teeth go beyond the first. During operation, the teeth of both wheels mesh at one point. And the crescent-shaped partition fills the void created by the tension roller. At this time, the liquid flows into the compartments and is locked by the gear teeth. Thus, the liquid moves from the inlet to the casing drain. Internal gear models use spur gears only.

Applications of gear pumping equipment

Such devices are well suited for pumping paints and varnishes, various oils, resins, liquids of increased (but not high!) Viscosity. The pressure on the operation of these devices has little effect, so they are ideal for situations where the supply of liquid substances is not made on a regular basis.

Gear pump advantages

Unlike piston ones, they do not create areas of increased pressure, but they have a high flow capacity. They differ in approximately the same way from centrifugal pumps, which generally do not tolerate viscous substances. If we give the closest example of a gear pump, then we can imagine an oil pump used in cars.

Industrial pumps of this type are capable of withstanding extremely high pressures at high flow rates - up to 200 bar. All this becomes possible thanks to the very rigid support on which the shaft is mounted.

Due to the fact that the speed of rotation of both gears is directly proportional to the productivity, these devices are perfect for mixing / dosing various liquid substances.

The gears themselves are made either of stainless steel or of cast iron, which allows them to work with aggressive liquids (and do not forget that the pipeline material must also have similar properties).Gear pumps are often used in heavy equipment to power hydraulic mechanisms.

Rating of the best self-priming pumps for industrial needs for 2020

Hose pumps

3rd place: Mouvex BackMer Pump A10-AS10

This device is designed for pumping aggressive and abrasive liquids for the needs of the mining and chemical industries. It will also be indispensable for the needs of water treatment and drainage. Perfect as a water treatment system for small reservoirs.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | France |

| Performance | 0.135 m3 / h |

| Pressure | 8.00 Bar |

| Pumped liquid temperature | 0-70 ° C |

| Self-priming | Yes |

| Abrasive | Yes |

| Maximum RPM | 90 rpm |

| Cylinder volume | 0.025 l |

| Price, rubles | 72000 |

- Affordable price;

- High-quality assembly;

- High temperature range of the pumped liquid.

- Low capacity and pressure withstand for an industrial unit

2nd place: Verderflex ROLLIT C-50

The model is designed for pumping various substances of high viscosity (even if they are saturated with abrasive inclusions and have a high specific gravity). It has excellent suction power for an industrial line, it is better applied in the fields of metallurgy, pulp and paper industry, pharmaceutical production.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | England |

| Performance | 24.5 m3 / h |

| Pressure | 4.00 Bar |

| Pumped liquid temperature | 0-40 ° C |

| Self-priming | Yes |

| Abrasive | Yes |

| Maximum RPM | 100 rpm |

| Cylinder volume | 0.03 l |

| Price, rubles | 93000 |

- Possibility of periodic work "dry";

- High pressure requirements at average flow rates;

- Explosion-proof housing.

- High price.

1st place: Verderflex VF40

This model has an extremely wide range of applications and is adapted for use in almost any industry - from food to chemical. Works perfectly with large foreign inclusions, crystallization products, high-viscosity media. The special design of the flow direction makes the hoses more wear-resistant.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | England |

| Hose diameter | 10-125 mm |

| Working temperature, degrees Celsius | -20 to +100 |

| The size of foreign inclusions, in% of the hose diameter | 25 |

| Chemical resistance to aggressive media | Yes |

| Productivity, m3 / hour | 90 |

| Maximum head | 150 |

| Price, rubles | 120000 |

- The hose is lubricated from the outside (full dry operation is possible);

- Wide range of applications;

- High performance.

- For complex technical equipment, the minimum warranty is only 1 year.

Screw pumps

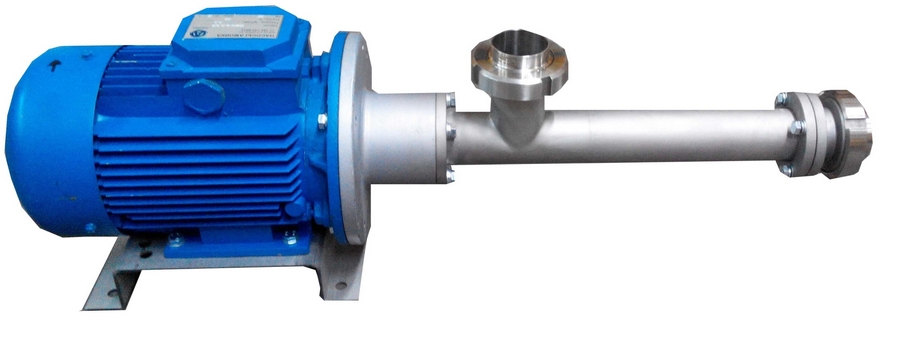

3rd place: Ampika OVN 8-4.0 / 5

This screw pump is a medium displacement model for pumping highly viscous substances in the food and pharmaceutical industries. The relatively slow rotation of the screw guarantees the preservation of the structure of the pumped substance. The model uses a monoblock design, which achieves increased stability.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Delivery, m3 / hour | 4 |

| Head, atm | 5 |

| Dimensions | 1030x280x280 |

| Weight, kg | 45 |

| Power, kW / rev. Min. | 1.5x1000 |

| Price, rubles | 71000 |

- Improved body;

- Affordable price;

- Relatively small dimensions.

- Small range of applications.

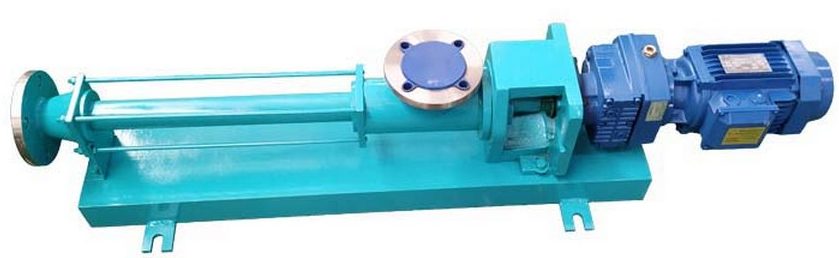

2nd place: NETZSCH-type-NM045

This model of increased capacity is designed for drainage and water treatment works. Interacts well with foreign inclusions. Can be upgraded by changing the shaft with a large number of stages. In the process of work, the principle of enhanced fluid transfer is applied by creating areas of increased pressure.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | China |

| Delivery, m3 / hour | 60 |

| Head, atm | 4 |

| Dimensions, cm | 170x30x40 |

| Weight, kg | 55 |

| Power, kW / rev. Min. | 3.4x1000 |

| Price, rubles | 120000 |

- Quite good suction power;

- Ability to maintain sufficient pressure;

- Relatively low weight for a monoblock.

- There may be problems with spare parts and warranty repairs.

1st place: RSP HWG120

This pump is designed exclusively for work in the construction industry, because its main purpose is to pump bitumen and liquid petroleum asphalt. Works great with highly viscous substances, especially if they have an elevated temperature (up to +400 Celsius). The casing is made in a special design, which prevents the leakage of harmful vapors from the pumped liquids into the external environment.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | China |

| Delivery, m3 / hour | 52 |

| Head, atm | 4.3 |

| Dimensions, cm | 170x30x40 |

| Weight, kg | 75 |

| Power, kW / rev. Min. | 4.4x1000 |

| Price, rubles | 1000000 |

- Ability to work with extremely aggressive substances;

- There is a case protection;

- The temperature regime practically does not matter.

- The device belongs to the professional category, so the price is absolutely not cheap.

Gear pumps

3rd place: Varisco G-38

This gear unit works on the principle of internal gearing (letter G in the name). Designed for pumping high viscosity substances, but without aggressive inclusions. It is used for transportation of oil, oil, fuel oil, fuel of various types. It has a good mechanical seal, which improves wear resistance.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Productivity, m3 / hour | 3.6 |

| Head, bar | 15 |

| Size of branch pipes, dm | 1 |

| Maximum viscosity, cP | 80000 |

| Rotation frequency, rpm | 1500 |

| Drive power, kW | 2.3 |

| Price, rubles | 38000 |

- The most adequate price / quality ratio in its segment;

- Improved internal structural elements;

- Fireproof enclosure protection.

- Does not work with aggressive / abrasive substances.

2nd place: Liverani Gear 50

This pump works on the external gear principle. Excellent for installation on long-distance vessels both in the engine compartment (for ferrying fuel oil) and as an additional power equipment for ship hydraulic units. The model is distinguished by an extremely budgetary price, which is not typical for the existing functionality.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Productivity, m3 / hour | 3 |

| Head, bar | 10 |

| Size of branch pipes, dm | 3.4 |

| Rotation speed, rpm | 300 |

| Maximum viscosity, cP | 20000 |

| Drive power, kW | 1.5 |

| Price, rubles | 40000 |

- Wide functionality;

- Budgetary price;

- Monoblock design.

- Does not work with high viscosity substances.

1st place: Bosch Rexroth PGH-2X-020 / r11VU2

This model is intended exclusively for strengthening the hydraulic units of construction machinery (excavators, tractors, etc.). Due to its use, the productivity of equipment is significantly increased. It is used for pumping oil, damping fluids, etc.

Specifications:

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Weight, kg | 20 |

| Dimensions, cm | 35x30x30 |

| Pressure, bar | 350 |

| Maximum pumping volume, m3 / hour | 250.5 |

| Price, rubles | 78000 |

- Increased power;

- Compact design;

- Comparatively inexpensive price for an industrial pump.

- Highly specialized and limited scope.

Instead of an epilogue

Before purchasing an industrial pump in Russia, you should seek the opinion of a specialist who can competently select the desired model. The peculiarities of the market for this industrial equipment in the Russian Federation are such that no one will ever post the real price of a new unit on the official website of a Russian dealer - the seller always asks first to fill out an online application, where it will be necessary to clarify some technical issues for future use.Therefore, it is possible to roughly estimate the cost of pumps only by viewing private ads where they are sold in second-hand condition. Accordingly, it is not a fact that it will be possible to find the desired model in the used lists, and even if so, the price of a new one may differ several times. Thus, on price issues, it is better to use the information of foreign manufacturing plants from their official websites. In addition, it is advisable to immediately discuss the issue of warranty repairs with the seller - especially this topic must be raised when buying screw pumps.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive medicines for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72463 -

Top rating of the best in 2020 means for male potency with a description

Views: 68296