Rating of the best sawing machines in 2020

At the moment, there is a huge variety of sawing machines. Whether it's expensive, powerful and high quality or budget with an average level of accuracy, or even a homemade machine built from a pile of scrap metal, they are all designed for a wide range of construction jobs. The list of these works includes the processing of various wood materials, carpentry and the construction of furniture for the home.

Brief information

This article contains all the information you need to know how to properly care for and work with woodworking machines. Fine tuning of equipment, maintenance of equipment, periodic and overhaul repairs, as well as further operation - all this is necessary for specialists and amateurs working on sawing equipment. Among other things, this review contains a short list of the best representatives of circular machines, which is divided into two categories. Before proceeding to familiarize yourself with the best equipment, it is worth reading the general parameters and characteristics of all sawing machines.

Machine parameters

First of all, such equipment is distinguished by the idling speed of the processing disk.

- Up to 2500 rpm - in this case, the machines are excessively large, because a V-belt transmission is located in their design, and it takes up a lot of space. On the other hand, the components of the case look simple and reliable, which will ensure easy repairs in the future. Such equipment is characterized by low speed, and it is this speed that, in turn, provides a high-quality cut of wood of any density in continuous operation.

- Above 2500 rpm - in such equipment, the rotation of the disk is provided thanks to the gearbox. This type of machine is not as reliable as with a V-belt transmission, but otherwise gives the design a noticeable compactness and mobility. Thanks to the reducer, the rotational speed of the disc is increased, and the quality of the processed surface will be much better.

Further, the machines may differ in the type of work table.

- Fixed-size table - these tables provide the ability to process wood materials up to one meter long. This allows the workpiece to be held by just one machine operator.

- Table with pull-out elements - in such equipment there are additional devices for workpieces exceeding 1 meter in length.

Also, the machines are distinguished by the peculiarity of the schemes, additional devices and capabilities, as well as other attributes of the system.

- Slow start - this feature significantly reduces the load when starting the engine.

- Deceleration of run-out - due to it, the time of rotation of the disk or other processing element after turning off the machine is noticeably reduced. This is very convenient for the machine operator - it reduces the likelihood of injury.

- Second run protection - in this case, the system warns the machine operator when there was a power outage. A very important function required for human safety.

- System overload protection - This feature automatically shuts down the motor in case of increased work load.

- A stabilizer of revolutions of rotation under a significant load - in other words, it is consumatic, which ensures a stable speed of rotation of the spindle under the influence of any load. Thanks to the consumation, the wood can be processed smoothly and confidently, and the engine, in turn, operates without overload.

- Stand for cross and oblique sawing - this possibility takes into account the presence of a special stand with a protractor, along which the required angle is set for the disc to work.

- Planing and planing - machines with these capabilities are usually equipped with a special removable shaft. Ultimately, taking into account the parallel stop, planing is obtained, and without it - planing.

- Thicknessing is a very useful feature that is not available in every machine. The essence of this function is the use of a special stand in which the height of the lumen can be adjusted. In the future, this gives the opportunity for uniform processing of the wood by pressing the material firmly against the planer element.

- The presence of technological holes required for the installation of additional equipment - in this case, it means manual installation of a jigsaw, cutter and other similar elements. Additional installation is possible with removable mandrels.

It is also worth paying attention to the classification of electric motors of woodworking equipment. This is very important for those who want to assemble the machine themselves.

- S1 - a category of professional equipment in which there is a possibility of continuous work;

- S6 - a category of medium equipment that has the ability to process materials with a smooth distribution of the load period and idle;

- S3 is a category of budget equipment, for which the duration of work is recommended no more than fifteen minutes. Next comes the shutdown of the engine until it cools completely.

Amateur machine tool group

The equipment of this group combines several criteria.

- First and foremost, the low cost of construction and parts;

- This is followed by light equipment repair and further maintenance;

- The latter is a mandatory revision and design adjustment. This applies not only to the design itself, but also to all electronic and mechanical components.

The main advantage of this type of equipment is the minimum cost of money required to create a working machine. Of course, this business will take a certain period of time, but in the end you will get a reliable unit that can process wood and various materials with high quality.

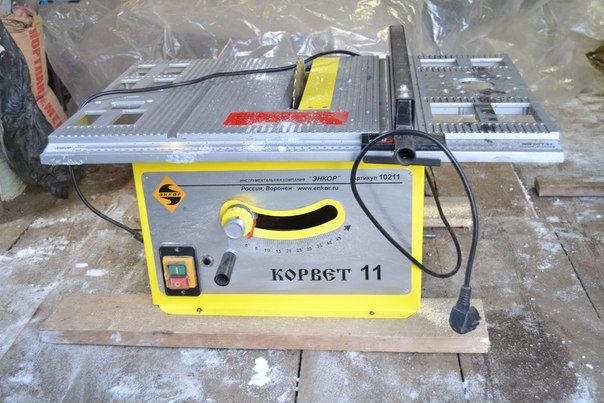

Machine Enkor Corvette 11

Cost - 12,000 rubles

Portable circular saw, equipped with a universal table with a collecting stand.

At first glance, this installation can please you with enough space for a router and jigsaws, low cost and the ability to cut wood with a thickness of 80 mm. The maximum thickness of wood can be processed with a basic disc. Here are all the benefits that can attract an inexperienced worker. However, this setup hides more flaws.

First of all, what is worth paying attention to are very weak threads and hardware, which quickly wear out during the installation of the stand. There are noticeable backlashes along the guides of the stop with the protractor. As a result, it will not be possible to repeat the additional pass from the end of the decorative part. It is rather inconvenient to adjust the parallel stops. It takes too long to move the stop plate. The processing disc tends to lower itself. In this case, it is unrealistic to maintain the required size the first time. This takes at least a few tries.

A serious drawback is the lack of a slow start, and in return there is a backlash located between the gears in the gearbox. Thanks to such a system, after a year of stable operation at the installation, it will be necessary to sort out the gears of the reducer. In connection with a quick start, there is a strong impact of the bearings against the rotary shaft of the engine. In this regard, it is undesirable to use the Enkor Corvette 11 without a special power supply unit that provides a slow start.

- Low cost;

- Availability of space for cutters and jigsaws;

- The ability to cut wood up to 80 mm.

- No slow start;

- Rapid wear of parts.

Specifications

| Characteristic | Value |

|---|---|

| Cutting depth 900-450, mm | 80 - 60 mm |

| Table and machine dimensions | 700x465 mm, 28 kg |

| Disc dimensions - outer diameter / inner diameter, mm | Split 260/30 |

| Drive data: power, transmission, speed, kW / rpm | 1.5 kW, gear transmission, 4 500 rpm |

| Diameter of the branch pipe connecting the vacuum cleaner, mm | 30 mm |

Ryobi RTS 1800 machine

Cost - 15,000 rubles

Circular machine equipped with a folding scissor support.

This unit is equipped with the most powerful engine of all the representatives of the amateur group. Thanks to its power, the processing tool (disc) can easily handle wood of any density.

Taking into account the possibility of instant clamping by means of a smooth movement, it is possible to quickly and accurately adjust the position of the processed material in the stop. The adjustment of the position of the disc, which implies the angle and height of the position, is also done with one lever. It is possible to quickly set up the riving knife without the need for tools.

The design of the machine is very conveniently developed - there is an electronic protection in the core of the unit, and the disc begins to move due to the presence of a slow start. It is also possible to smoothly extend the desktop. The machine body contains a modest storage for all the necessary keys, processing tools and small workpieces.

Ryobi RTS 1800 is considered an inexpensive sawing machine. The cost of 15,000 thousand easily justifies all the convenience and capabilities of the machine.

Among the shortcomings can be noted periodic minor defects that are found on the surface of the desktop in some models. It is best to pay attention to such nuances during the purchase of the unit. When attaching materials, you need to carefully monitor the engine position mounting racks, as well as the corner stop. The fact is that the emphasis is rather weak, and the mounts are not designed reliably.

The Ryobi RTS 1800 starter configuration only sold for about a year. It is not known why, but after a while the retractable table disappeared from the machine. In this case, you will have to buy the table separately.

The next problem is the rapid wear of the bearings. It only saves that the standard castors are easily swapped for SKF bearings.

The most important thing that the buyer needs to take into account before purchasing this machine is that it is quite difficult to find parts on the territory of the Russian Federation. Ryobi has relatively poorly developed its service network in the Russian Federation. It is not a fact that new parts will be cheaper than a new machine.

- Powerful engine;

- Pull-out table;

- Disc adjustment;

- Availability of tool storage;

- Smooth start capability;

- Electronic protection.

- Weak engine mount;

- Very fast bearing wear;

- Poorly developed service network of the company.

Specifications

| Characteristic | Value |

|---|---|

| Cutting depth 900-450, mm | 80 - 60 mm |

| Table and machine dimensions | 560x710 mm, 27 kg |

| Disc dimensions - outer diameter / inner diameter, mm | Split 255/30 |

| Drive data: power, transmission, speed, kW / rpm | 1.8 kW, gear transmission, 4 500 rpm |

| Diameter of the branch pipe connecting the vacuum cleaner, mm | 75 mm |

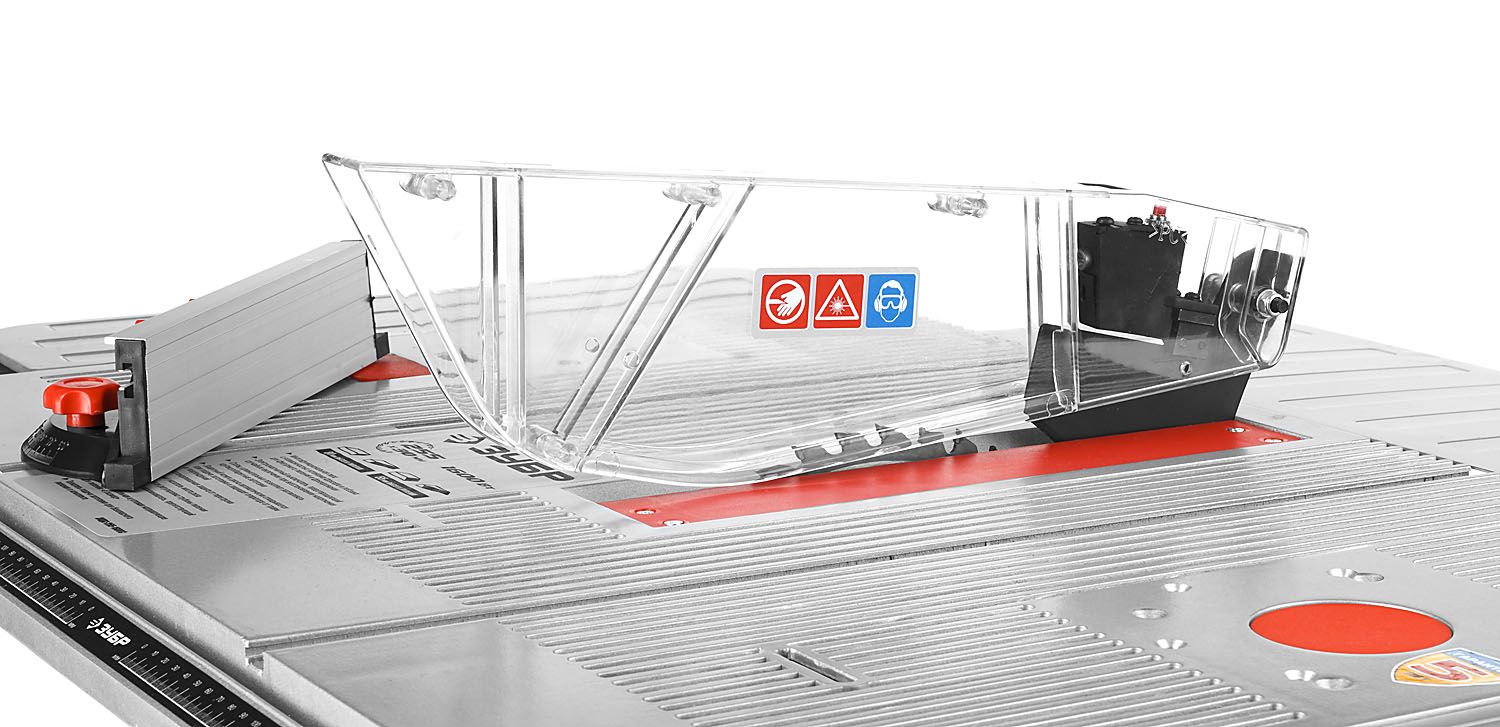

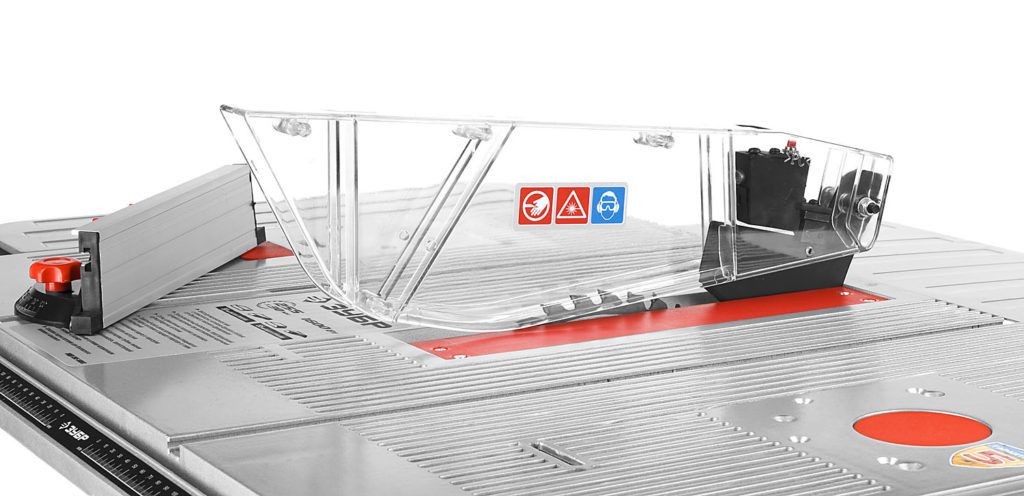

BISON machine ZPDS 255 1600S

Cost - 17,000 rubles

Machine with table saw, multiple extendable tables and additional space for auxiliary tools.

This machine is a prominent representative of household appliances, which has a high cost and numerous disadvantages. First of all, the seemingly useful laser pointer for the cutting stroke is striking. However, this unit is poorly attached to an unbalanced stand, which ultimately affects the accuracy of the beam pointing. It is also inconvenient that the parallel stop, which is held on the device from both sides, cannot be aligned with the ruler. In this case, alignment will have to be relative to the direction of the disc.

There are seats for the milling cutter and jigsaw - and this is kind of a plus, however, it will not be so easy to install them. This will require additional preparation of seats and reliable adapters.

According to the passport, the machine has an extension of the working space for the processing disc in the size of 85 mm. However, as a result of the fact that the engine's power is only 1.6 kW and thermal protection is installed in it, the overheating sensor is triggered and because of this it is not even possible to process a surface with a diameter of 80 millimeters. When creating the machine, the designers installed a lock from being switched on again - it seems to be convenient, but subsequently there is no slow start in the system.

Not surprisingly, many buyers are reluctant to buy this machine and prefer more expensive options. Everything is quite logical, because few people want to work on that machine, in which there are painfully many flaws. Moreover, this is directly related to the lack of warranty support.

The manufacturer, in turn, declares that it is ready to fulfill its warranty obligations even if defects appear after the purchase of the machine.

- The presence of a laser pointer;

- Presence of seats for serial tools;

- High engine power.

- Weak fastening for the laser pointer;

- Lack of soft start;

- Inability to align the parallel stop along the ruler;

- Additional preparation of seats for serial tools.

Specifications

| Characteristic | Value |

|---|---|

| Cutting depth 900-450, mm | 80 - 60 mm |

| Table and machine dimensions | 725x499 mm, 20 kg |

| Disc dimensions - outer diameter / inner diameter, mm | Split 255/30 |

| Drive data: power, transmission, speed, kW / rpm | 1.5 kW, gear transmission, 4 500 rpm |

| Diameter of the branch pipe connecting the vacuum cleaner, mm | 40 mm |

Professional machine tool group

Each model from the range of professional machines is specially designed for long-term work under heavy loads. Such equipment is characterized by increased power, resistance to permanent mechanical deformation, long service life, etc. Professional circular machines are divided into several categories:

- Mobile machines;

- Stationary machines;

- Narrow profile;

- Universal;

- Gear driven machines;

- V-belt driven machines.

Belmash SDM 2000M machine

Cost 29,000 rubles

This Belarusian machine is a powerful multi-tasking equipment designed for processing any wood materials.

The main advantage of this Belarusian equipment is its versatility.

In addition to the usual cutting work, the machine can:

- Saw and mill with a disc tool;

- Carry out jointing, thicknessing and planing of wooden materials on a planer;

- Drilling is possible, as well as the selection of short blind and through grooves in workpieces. The grooves are taken on a special auxiliary table, which is fixed in the area of the chuck. When working on saw, planer and drill / milling tables, interaction with the other pull-out units is limited.

This equipment is fairly easy to set up. The fact is that during adjustment there is no need to carry out any interactions with the belt drive units.

Among the disadvantages of the device is the absence of a slow start, as well as the impossibility of automatic redirection of materials for thicknessing attachments. You need to redirect wood and other materials by hand, which ultimately creates a problem. The bottom line is that the wood thickness limit is 70 millimeters, which is relatively good. However, it will be quite difficult for one person to push a tree of this size over the processing surface. In addition, the design itself does not inspire confidence, especially when working with materials of this thickness.

When setting up the working tools of the equipment, it is worth, as it should, adhere to the safety rules during operation. The problem is that if the wing nut is loosely tightened, the disc tool can jump above the level of the work table. This cannot be avoided even in the case of a slow start function, the whole problem is in the significantly overstated engine power.

- Multifunctionality of equipment;

- The ability to quickly and easily configure the device;

- Ease of use;

- Machine mobility;

- High engine power.

- No slow start;

- Periodic jumps of the disc with a weak tightening of the nut;

- Lack of automatic feeding of wooden materials.

Specifications

| Specifications | The values |

|---|---|

| Cutting depth 900-450, mm | 85/55 |

| Table and machine dimensions | Saw 732x456, planer 760x247, milling 410x190 |

| Sizes of a disc, disk cutter, end mill, planer shaft, mm | 250 - 32 mm; 125-32 mm; 6-12 mm; width 230 mm |

| Drive data: power, transmission, speed, kW / rpm | V-belt transmission, disc 2 850 rpm, end mill and planer shaft 7 700 rpm |

| Diameter of the branch pipe connecting the vacuum cleaner, mm | 28 mm, 38 mm, 63 mm |

Bosch GTS10 XC

Machine cost - 60,000 rubles

Table saw with movable slide and table extension and table extension.

This machine has the best performance than any other sawing machine on this list. The advantages of the machine include high engine power, a durable metal table and a wear-resistant rip fence with easy control. It is because of these parameters that this machine can work with wood of any strength. In addition to excellent characteristics, the device has a reliable movable carriage, expander, extension, as well as a capacious angle stop. Due to the presence of such units, with the help of the machine, you can make various forms of products, including decorative and applied products, overall dimensions of furniture and other wooden elements. Any moving unit can be easily adjusted in the machine. With the help of a special holder, it is possible to remove all emerging backlashes.

For complete safety of the worker, the machine has a special protective screen, a powerful insert plate and a brake for the run-out of nozzles. Reliable operation of the engine is ensured by a slow start, an overload protection system and an automatic feed.

On the downside, only the high cost of equipment can be noted.

- High power equipment;

- Great functionality of the machine;

- Several processing modes;

- Sturdy bed.

- High price.

Specifications

| Characteristic | Value |

|---|---|

| Cutting depth 900-450, mm | 80 - 60 mm |

| Table and machine dimensions | 1210x1288 mm, 35 kg |

| Disc dimensions - outer diameter / inner diameter, mm | 254-30 mm |

| Drive data: power, transmission, speed, kW / rpm | gear transmission, 2.1 kW, 3 200 rpm |

| Diameter of the branch pipe connecting the vacuum cleaner, mm | 30 mm |

Output

Judging from all the available information, it can be argued that the best representative of the sawing machines in this review is the Ryobi RTS 1800. The device has sufficient power, a bunch of serious possibilities from the electronics side, good durability and maintainability. If you have the necessary spare parts, the best option would be to purchase this particular machine.The fact is that the further experience that will appear during long-term work with this equipment will make it possible to remake it for any conditions and needs. In home use, it will be indispensable, and Ryobi will not hit your pocket too much.

However, this rating is not a guide to buying; you should only buy a sawing machine after consulting a specialist.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive drugs for flu and colds for 2020

Views: 91750 -

The best men's running shoes in 2020

Views: 87680 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296