Rating of the best manufacturers of cellular polycarbonate for 2020

Every year the building materials market amazes with its novelties. Cellular polycarbonate, although not something new, is still popular and in demand among both private and industrial builders. It attracts attention with such qualities as excellent thermal insulation, resistance to high and low temperatures, low weight, impact resistance, etc.

The nuances of choosing cellular polycarbonate

The huge variety of cellular polycarbonate on the building materials market confuses the ordinary person. Questions immediately arise: how to choose high-quality material at an affordable price, which characteristics are important in the first place, and which are secondary. We will try to give some practical advice on how to choose polycarbonate and what to look for when buying it.

Before delving into the technical characteristics, you should decide what the material is being purchased for. Most often in private construction, polycarbonate is used for greenhouses, sheds, arbors, fences. Depending on the functions that polycarbonate will perform, the appropriate characteristics will be selected. So, we pay attention to the following characteristics:

- thickness and structure.

The thickness of polycarbonate sheets can be 4, 6, 8, 10, 16, 20, 25, 32, 40 mm. Lightweight versions are available with a thickness of 3.2, 3.7 mm. For greenhouses that cannot be disassembled for the winter, sheets with a thickness of 6-8 mm are more suitable. Thicker ones will let in less light, which is so necessary for plants. Sheets with a thickness of 3.7-4 mm are suitable for greenhouses with a milder climate and no heavy snowfalls. Small sheds, gazebos are best done with a material thickness of 6-8 mm, for the roof it is better to use a thickness of 16 mm.

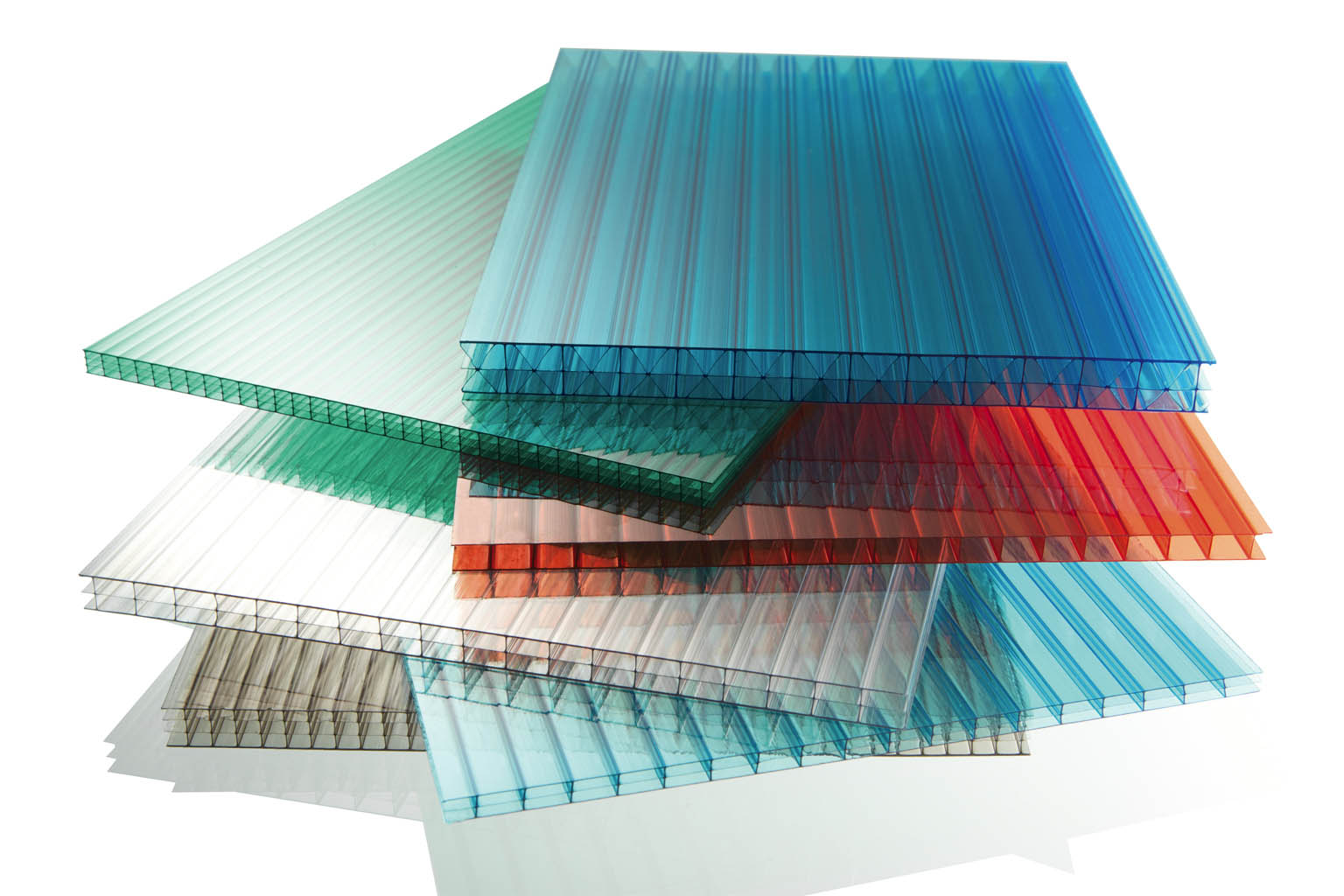

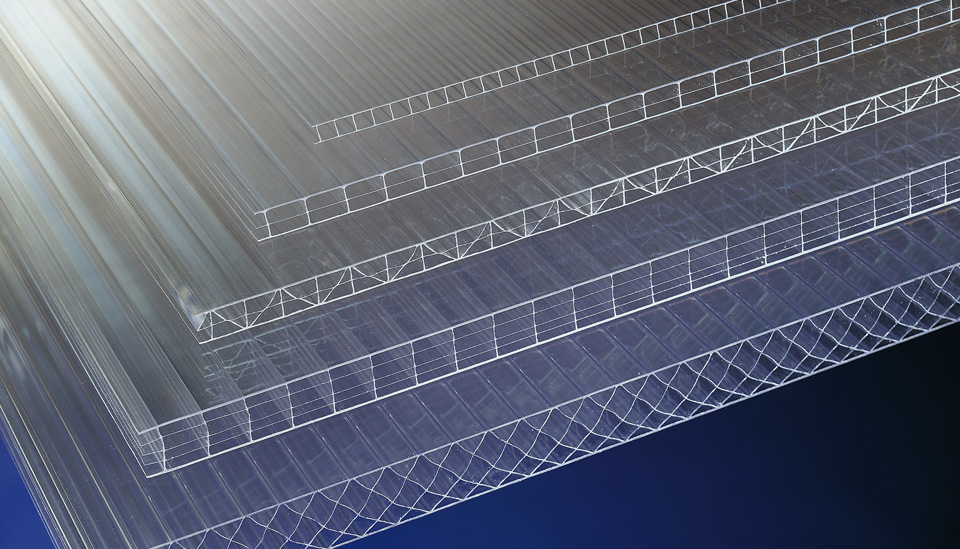

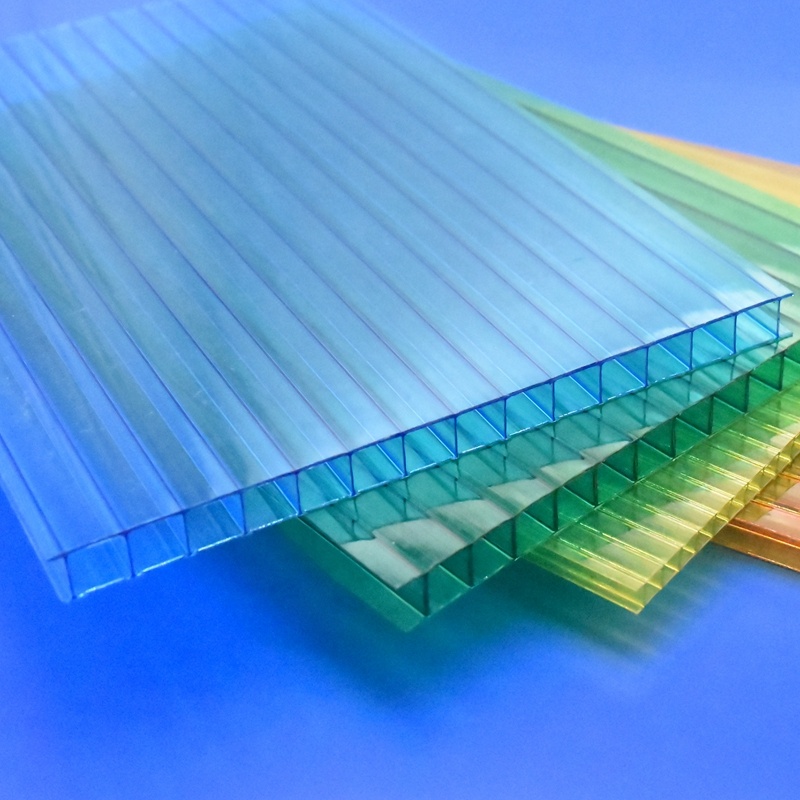

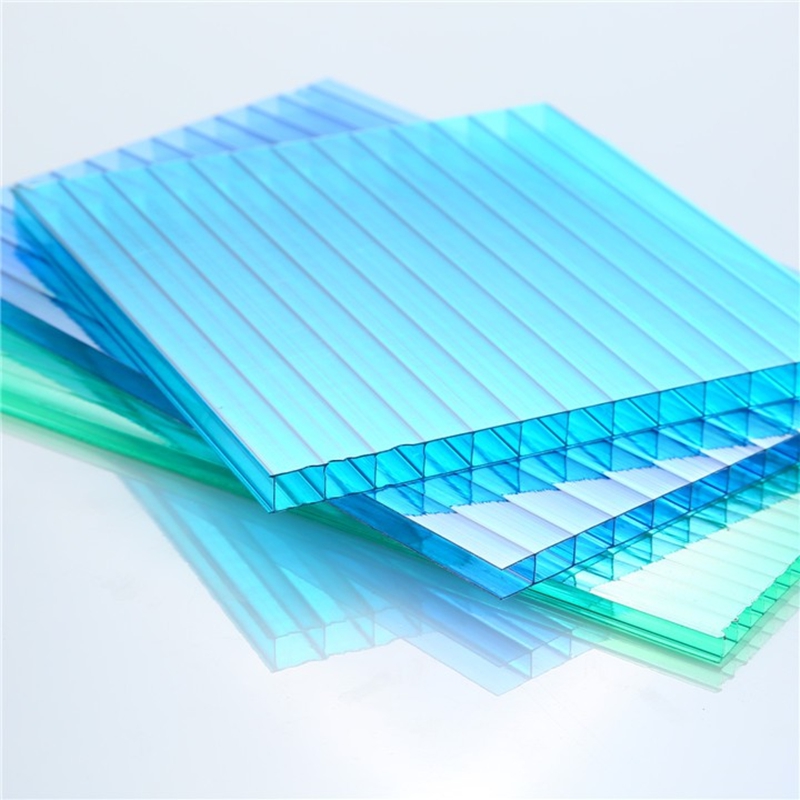

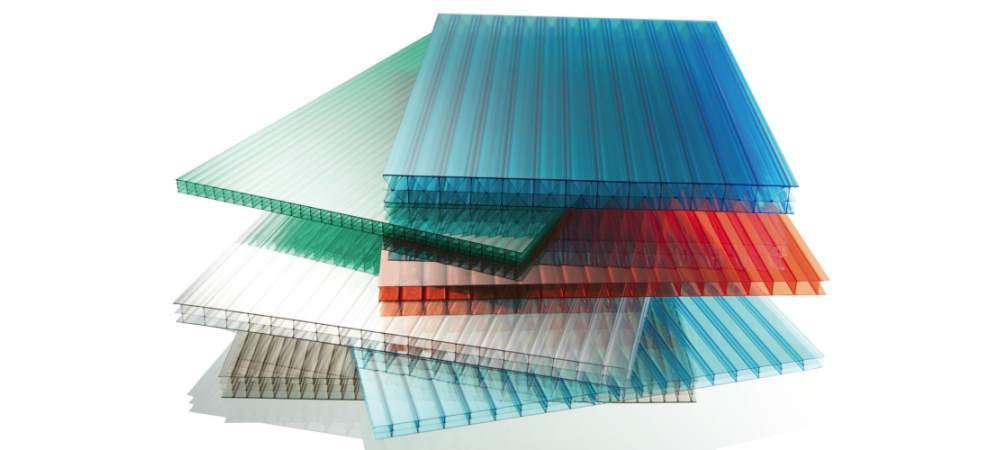

One-, two-, four- and six-chamber cellular polycarbonate is distinguished by structure. They differ in the number of layers connected by jumpers. In addition, a different arrangement of jumpers is possible (H-shaped and X-shaped), which also affects the resistance to shock and other mechanical stress.

- density.

The strength of the material and the ability to withstand negative weather influences (snow, wind, hail) depend on this indicator. The density value varies between 0.52-0.82 g / cm3... Sheets of the same thickness can have different densities, it depends on its structure (the number of bridges). Logically, the denser the sheet, the heavier it is.

- weight.

Weight directly depends on the density of the sheet. Accordingly, the lighter the sheet, the less dense and less impact-resistant it is. Some manufacturers produce lightweight versions of polycarbonate sheets, but at the same time they must be marked with a special word, for example, Light. In world practice, the production of this material is considered to be the standard sheet weight of 1 m2 the following indicators: 4mm - 0.8 kg; 6 mm - 1.3 kg; 8 mm - 1.5 kg, 10 mm - 1.7 kg.

- UV protection.

Without UV protection, polycarbonate begins to deteriorate in 2-3 years under the influence of sunlight.Therefore, manufacturers apply a special protective layer to increase the service life. The service life of UV-protected polycarbonate is over 10 years. Depending on the technology of applying the protection, this period can be up to 30 years. The presence of a protective layer is reflected in a special marking.

- minimum bending radius.

This characteristic is important when using sheets for the installation of curved structures (arched greenhouses, awnings, gazebos). This indicator depends on the thickness and structure of the sheet and is 0.6-2.8 m. It is advisable not to exceed the permissible bending radius in order not to disturb the structure of the sheet and the UV protective layer.

- light transmission capacity.

This parameter depends on the thickness of the sheet, its color and transparency. For different manufacturers, this parameter for transparent polycarbonate with a thickness of 4 mm varies from 80 to 95%. The thicker the sheet, the less light transmission.

Having figured out what to look for when buying this material, you can start choosing. We have presented to your attention the best manufacturers of polymeric materials and their trademarks of cellular polycarbonate.

The best polycarbonate manufacturers

Plazit Polygal Group (Polygal Vostok)

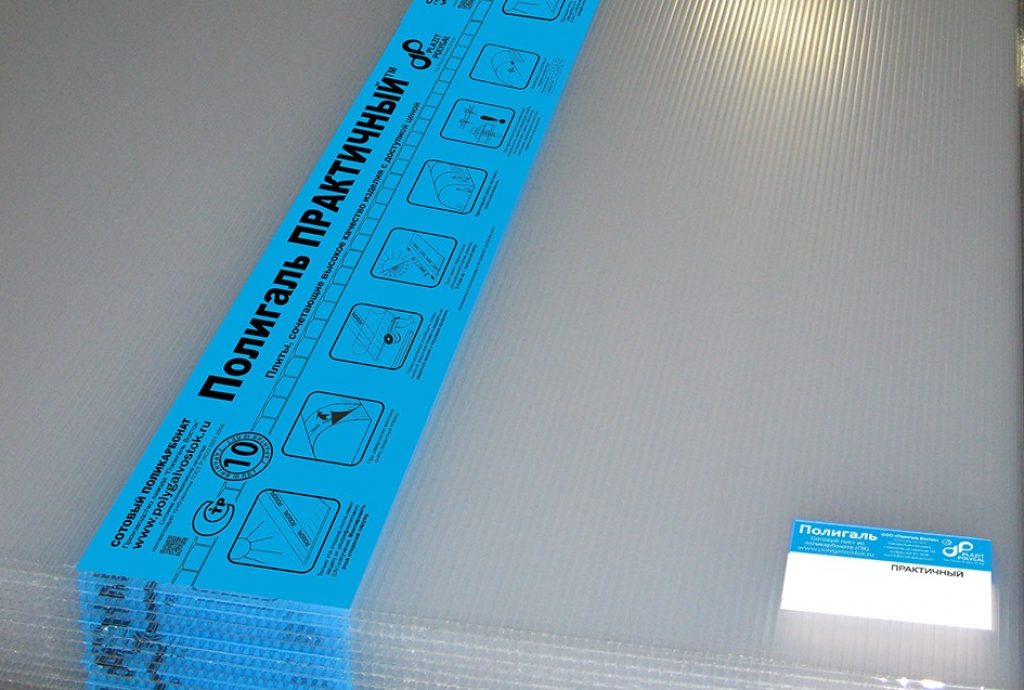

Polygal Vostok is a domestic official representative of the Israeli company Plazit Polygal Group. The company has been manufacturing polymer boards for over 40 years. Its products are not only in demand all over the world, but also are the quality standard.

Polygal Vostok produces cellular polycarbonate 4-20 mm thick, 2.1x6.0 and 2.1x12.0 m in size. The color palette includes 15 colors. In addition to the standard (transparent, white, blue), we offer garnet, amber, silver, gray and other colors. The company offers the following types of polycarbonate:

The GOST standard is recommended for roofing for various purposes. Thickness 4-20 mm. Sheet length 6.0 and 12.0 m. Available in the entire color palette named above. UV protection applied by co-extrusion. 15 year warranty.

Practical - a complete analogue of the GOST Standard, but with a 15% reduction in the specific weight of the sheet. 14 year warranty.

The Titan Sky standard is recommended for roofs with a slight slope, industrial structures that require special strength. Suitable for cold climates and difficult weather conditions. The reinforced X-shaped structure makes the sheets not only the most impact-resistant, but also contributes to the increase in the thermal insulation properties of the material. Thickness 8-20 mm. Available in all colors and with shading or reflective finishes.

Cellular hummingbird is a lightweight and economical option for the domestic market. Thickness 3.7-20 mm. 10 year warranty.

Kiwi cellular is an economical material for advertising purposes and summer residents. Thickness 3.2, 3.7, 4, 6, 8, 10 mm. The sizes are standard. 7 years warranty.

All subtypes of produced polycarbonate can be produced, upon customer's request, with additional coatings, embossing and flame retardants.

The cost of a sheet of 4 mm 2.1x6.0 m from 2500 rubles.

- when ordering from the manufacturer, it is possible to apply additional coatings: anti-fog "Antifog", absorbing IR and thermal radiation "Comfort", decorative embossing "Frieze";

- it is possible to manufacture polycarbonate with a special additive that inhibits the combustion process - the FR combustion inhibitor;

- decent quality at an affordable price;

- several options for the produced sheets by specific weight: standard, lightweight, reinforced;

- light transmittance at 82%.

- not found.

Covestro

The Italian company Covestro, which until 2015 was called Bayer MaterialScience, is a manufacturer of Makrolon brand polycarbonate. The use of innovative technologies in production allows us to produce high-quality material that is in demand by consumers with excellent characteristics. Polycarbonate sheets are produced with a thickness of 4, 6, 8, 10, 16, 20, 25, 32, 40 mm. The size of the sheet is standard 2.1 by 6.0 m. The color range includes colors: transparent, milky, blue, green, smoky, etc.

The service life of this brand of polycarbonate in outbuildings is up to 15 years.This period may be 20-25 years, but it depends on the correct storage and further operation of the material.

- the excellent technical characteristics of the material are due to the high-quality raw materials (100% virgin raw materials, not recycled secondary) that the company uses;

- refractory;

- does not emit harmful and toxic substances during combustion;

- maximum impact resistance among similar materials from other manufacturers;

- resistance to chemical influences (atmospheric phenomena, reagents);

- high heat and sound insulation;

- the ability to use at high temperatures (low coefficient of thermal expansion);

- not afraid of sudden changes in temperature;

- a water-repellent layer (no drop marking) on the inside of the sheet to prevent the formation of condensation drops (water drains without lingering);

- the presence of a coating that protects against harmful UV rays;

- light transmittance up to 95%.

- the manufacturer offers only one size 2.1 by 6.0 m;

- small range of colors.

Carboglass

The Carboglass company is a pioneer in Russia in the production of cellular polycarbonate. Currently there are 4 production lines in Golitsyno and Krasnoyarsk. The production uses industrial equipment of the Italian company OMIPA S.p.a. OMIPA S.p.a. Granules are purchased only from primary raw materials from leading manufacturers Styron, Kafrit, Covestro and Kazanorgsintez.

Carboglass offers consumers one-, two-, three-, four-chamber versions of polycarbonate, as well as reinforced, which other manufacturers on the country's market cannot offer. Thickness of sheets 4, 6, 8, 10, 16, 20, 25 mm. Sizes 2.1 by 6.0 and 2.1 by 12 m. 15 colors are available (transparent, white, bronze, brown, red, yellow, turquoise, etc.). All polycarbonate from this manufacturer is coated with a protective UV layer using coextrusion technology.

Cellular polycarbonate of the Carboglass company is divided into 6 types, which differ in purpose and performance:

- Premium - for complex engineering structures, year-round greenhouses. Available in 4-25 mm thick. UV layer 40-60 microns. Resistant to UV radiation and adverse weather conditions (frost, hail, snow, wind). All colors are available in the 4-10 mm range. 20-year warranty.

- Reinforced (with a reinforced structure) - for structures with increased strength and greenhouses for year-round use. UV layer 40 microns, thickness 4 and 6 mm. Available in transparent version only. In addition to resistance to the manifestations of bad weather, it is resistant to shock loads. 20-year warranty.

- The crystal is used for seasonal greenhouses, private construction that does not require increased strength. Thickness from 4 to 25 mm. UV layer 30-50 microns. Resistant to frost and wind. Available in 9 colors in thicknesses up to 10 mm. 15 year warranty.

- Agro is used for seasonal greenhouses. Available in transparent 4 mm thickness. It has a high light transmission. For protection from UV radiation, it is covered with a protective film of 30 microns. Resistant to the manifestations of bad weather. 18-year warranty.

- Special for greenhouses and Super Cover - Agro economy options. The thickness is 3.5 mm and 3 mm, respectively, the UV layer is 10 microns. Transparent. 6-year warranty.

The cost of a sheet with a thickness of 4 mm and a size of 2.1 by 6.0 m is from 3650 rubles.

- all polycarbonate has a protective layer against UV radiation;

- one to four-chamber polycarbonate options, as well as with a reinforced structure;

- High impact resistance of Premium and Reinforced polycarbonate;

- light transmission up to 86%;

- temperature range of use -40 - +120 0FROM;

- fire-resistant and self-extinguishing material;

- chemically resistant material to many substances (except for ammonia, acetone, gasoline, kerosene and some others);

- wide opportunities for use from agriculture and private needs, to larger-scale construction;

- a large selection of colors.

- individual cases of non-compliance with the declared density.

SABIC Innovative Plastics

Sabic is a world leader in the supply of high strength sheet materials. It produces the Lexan cellular polycarbonate trademark, which has been present on the world market for over 40 years. Lexan material has a wide range of applications: interior work, glazing of various objects (greenhouses, swimming pools, verandas, winter gardens), walls and roofs of buildings, including industrial ones. Sabic offers its customers one-, two-, four-chamber and reinforced polycarbonate sheets of various thicknesses: 4.5, 6, 8, 10, 16, 20, 25, 32, 40, 45, 50 mm. Lexan sheets, along with such characteristics as high impact resistance, elasticity, good thermal insulation, fire resistance, have such an important quality as maintaining light transmission over a long service life. Thus, Lexan materials are indispensable for glazing buildings. Separately, it is worth highlighting protection against UV radiation. It is applied using a special laminating (varnishing) technology on one or both sides of the sheet and practically does not transmit UV and IR radiation.

The manufacturer offers several options for sheets, we will consider each of them in more detail:

- LEXAN THERMOCLEAR-PLUS ™ - UV protection on both sides of the sheet, thickness from 4.5 mm and more. High light transmission and a high degree of weather protection. 10 years warranty.

- LEXAN THERMOCLEAR SUNXP ™ has UV protection with even greater UV resistance than the previous version. 15 year warranty.

- LEXAN THERMOCLEAR Easyclean are self-cleaning sheets due to the use of a hydrophobic coating that reduces the formation of condensation drops. This, together with double-sided UV protection, increases light transmission, even in cloudy and rainy weather. 10 year warranty.

- LEXAN THERMOCLEAR Dripgard is a polycarbonate coated to prevent dripping on the inside. Indispensable for glazing verandas, swimming pools, greenhouses, industrial facilities, where droplets are unacceptable. 10 year warranty.

- LEXAN THERMOCLEAR Solar Control IR is a sheet with double-sided UV protection, increased resistance to negative weather conditions and impacts. But the main distinguishing feature is the blocking of near-infrared radiation, combined with maximum light transmission. Those. the room will be as illuminated as possible, but at the same time it will not be very hot inside. It is presented in a transparent version with a blue, light green or gray tint.

- LEXAN THERMOCLEAR Solar Control - the special inner surface of the sheets reduces heat accumulation while maintaining high light transmission values. 10 year warranty.

- LEXAN THERMOCLEAR Venetian is a polycarbonate with one side UV protection. It differs from others in white stripes on the inside of the sheet, which have a decorative effect. 10 year warranty.

- LEXAN THERMOCLICK - polycarbonate sheets with X-structure and UV protective layer on the front side. The advantage of this type is the absence of the need to install a vertical profile and the possibility of constructing non-profile facades. In addition, this type of polycarbonate has a high impact resistance and thermal insulation. 10 year warranty.

The cost of a sheet of 2.1 by 6.0 m with a thickness of 4 mm is from 4300 rubles.

- unique technology of protection against UV radiation;

- possibility of use in a wide temperature range (from -40 to +1200FROM);

- resistance to negative atmospheric influences, including hail;

- solar transmission can vary from 38 (tinted sheets) to 83%;

- sheets transmit sunlight well, but not heat (the room is illuminated, but not heated);

- the material is fire-resistant, resistant to mechanical stress, shock. Retains rigidity even at high temperatures.

- small selection of colors;

- more expensive than other manufacturers.

POLYALT

PK POLIALT is a Russian plant for the production of cellular polycarbonate under the Sellex trademark. Sellex materials are of the same quality as their foreign counterparts. The plant uses granules from Bayer as raw materials, and production is carried out on the Italian technological lines OMIPA.It is important to note that all employees of the plant involved in the production of polycarbonate underwent special training at OMIPA in Italy.

The POLYALT plant produces polycarbonate sheets with the following characteristics: thickness 3.3, 3.6, 4, 6, 8, 10, 16 mm; dimensions 2.1x6.0 and 2.1x12.0 m. All sheets are produced with UV protection with a layer thickness of at least 30 microns. The color range includes 12 colors: blue, brown, bronze, red, orange, silver, cherry, green, turquoise, transparent, milky, yellow.

Consider the varieties of cellular polycarbonate for various purposes, which are allocated by the manufacturer.

- Sellex Comfort - sheets are intended for glazing translucent structures. Thickness 4-16 mm. Available in two sizes. Available in all of the above colors. UV protection 35 microns. This type of polycarbonate sheet withstands all negative weather conditions, including snowfalls and strong winds. Differs in impact resistance. Light transmission up to 80%. Can be used in a temperature range of -450C- + 750C. 15-year warranty.

- Sellex Premium - is similar to the previous one in its characteristics, but has greater resistance to high temperatures. Can be used at temperatures from -45 to +1200C. Also, this polycarbonate is characterized by resistance to chemical attack and fire resistance.

- Sellex Solaris is a polycarbonate designed for glazing greenhouses, summer verandas, canopies and gazebos. Available in 4-10 mm thick. UV protection from 35 microns. Available in two sizes 2.1x6.0 and 2.1x12.0 m. All colors are available. 10 year warranty.

- Sellex Matador is an economical option for greenhouses, gazebos and verandas. Sheet thickness 3.3 mm, UV layer 30 µm, available in two sizes. 7 years warranty.

The cost of a sheet with a thickness of 6 mm and a size of 2.1x6.0 m from 3900 rubles.

- focused on difficult weather conditions (heavy snowfalls, winds, hail);

- resistant to temperature changes;

- long warranty period;

- wide range of applications: from private to industrial construction;

- has good sound and noise insulation.

- no sheets thicker than 16 mm in the production line;

- light transmission is lower than that of other manufacturers (up to 80%).

The world of polycarbonate

Mir Polycarbonate is a specialized polycarbonate manufacturer in Moscow. Particular attention is paid to the quality of the materials produced. All material is certified.

The plant produces polycarbonate with the following characteristics: thickness 3.5, 4, 6, 8, 10, 16, 20, 25, 32 mm; sheet sizes 2.1x6.0 and 2.1x12.0 m. Available in 12 colors. The company produces polycarbonate of two quality classes - standard and premium.

Class Standard is available in thickness 3.5-32 mm. From a thickness of 16 mm, the sheets have a triangular cross-section (2RX structure) and are more impact-resistant. Size range polycarbonate class standard is available in all colors (12 colors). Depending on the thickness of the sheets, they can be used both for small greenhouses and canopies (3.5-6 mm), and for larger private and industrial facilities (8-32 mm). Transparency from 80 to 85% (for sheets 3.5 mm).

The Premium class is produced in a thickness of 4-10 mm with a 2R structure in 12 colors. Premium features a double-sided UV-resistant coating (up to 60 microns). Only one size is available, 2.1 x 12.0 m.

The cost of a sheet of 4mm 2.1x6.0 m from 1500 rubles.

- all products are certified;

- the lowest price;

- focused on use in difficult weather conditions (snow, hail, etc.);

- the color range includes 12 colors;

- sheets with a thickness of up to 32 mm and a reinforced structure are produced;

- fireproof (do not burn, but melt);

- double-sided UV protection for premium polycarbonate.

- the manufacturer did not indicate information about the protective layer against UV radiation in the Standard class.

SafPlast

SafPlast plant is an expert manufacturer of polymer materials in Russia. It produces polycarbonate under the Novattro brand.To maintain the quality of manufactured products at a high level, only Italian equipment (OMIPA) is used and continuous control at all stages of production. The plant is equipped with its own laboratory, which checks all the main characteristics of the polycarbonate produced.

Novattro is produced in two sizes 2.1x6.0 and 2.1x12.0 m. Thickness 4-32 mm. Depending on the thickness, the sheet can be one-, two- and four-chamber, and its structure is 2R or 2Rx. The sheets are available in 12 colors, as well as in Decor format with patterned inclusions. The protective layer against UV radiation is 40-60 microns. Light transmittance up to 81%.

Polycarbonate for greenhouses stands out separately. It is produced under the ACTUAL brand! Bio. Its characteristics: thickness 4-10 mm, dimensions 2.1x6.0 and 2.1x12.0 m. UV protection from 35 microns. 80% light transmission. A special layer of Bio promotes accelerated plant growth and faster ripening of fruits.

Also, the manufacturer allocates a separate series of material for private needs in construction - Rational (Kazansky). Its characteristics: 2 above-mentioned sizes, thickness 3.5-10 mm, available in 10 colors. UV protection 30 microns. Can be used for greenhouses, arbors, canopies, etc. 10-year warranty.

The cost of a sheet of 4 mm 2.1x6.0 m from 3400 rubles.

- several options for the structure of the sheet: ordinary, reinforced and super strong;

- sheet thickness from 4 to 32 mm;

- specially developed material for greenhouses with a special Bio-layer (proven by research);

- a large selection of colors.

- the linear change in dimensions with increasing temperature is greater than that of the declared competitors.

When choosing cellular polycarbonate, it is important, first of all, to determine its functional purpose in combination with the weather conditions in your region. And only then, based on this, to select the types of material that are suitable for the characteristics. It will be easier to decide on the manufacturer, because we have provided the best for you.

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97660 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95020 -

Rating of cheap analogues of expensive drugs for flu and colds for 2020

Views: 91750 -

The best men's running shoes in 2020

Views: 87680 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84800 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77201 -

Ranking of the best action cameras from China in 2020

Views: 75268 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best means for male potency in 2020 with a description

Views: 68295