Rating of the best stone cutters for 2020

A stone cutting machine is needed for precise processing of modern building and finishing materials: concrete, granite, marble, ceramic tiles. Also suitable for cutting small blocks. In contrast to hand tools, it is more efficient and easier to use. How to choose a stone cutter, we will talk below

Benefits when using

When working with a power tool, the use of a guide is not required, which greatly speeds up and simplifies the process. Stone cutting equipment can be used to work not only with ceramic, but also with paving slabs, natural stone, and porcelain stoneware.

Disadvantages of professional and semi-professional equipment are cost and relative complexity in maintenance (compared to hand tools).

The main criterion for choosing is the depth of cut on different materials, productivity (if you plan to use the machine for permanent work), the maximum length of the element allowed for processing.

It is also worth considering the power and location of the engine:

- The choice of power depends on the type of material being processed. So with a sharp thin and sufficiently soft ceramic tile, facing artificial stone, models of 1.5 kW will cope. For thick, hard material such as porcelain stoneware, it is better to use a 2.2 kW machine. In some cases, equipment operating from a 380 V network is used. The more powerful the engine, the more efficient the work on the machine will be.

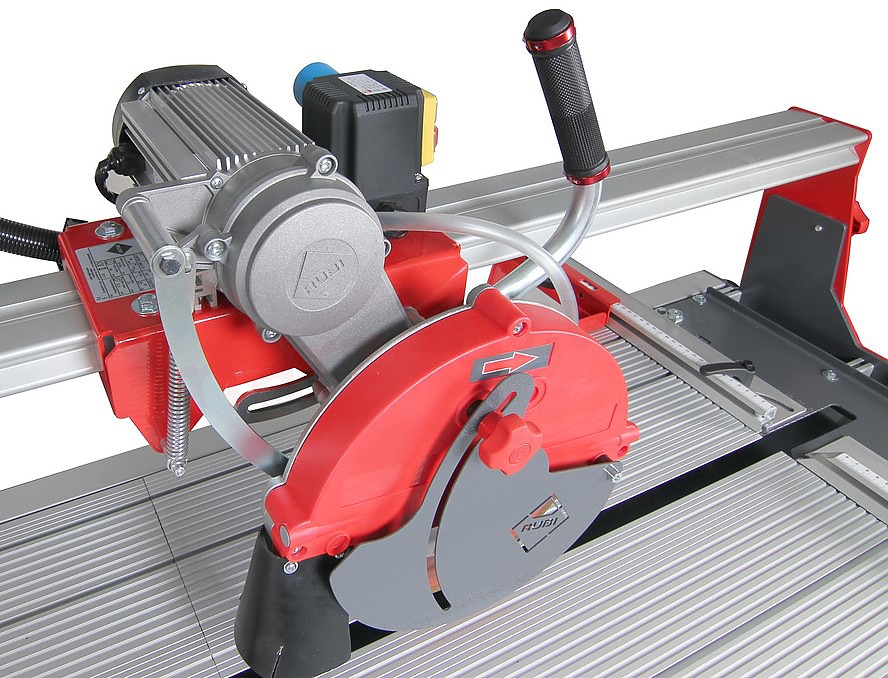

- Bottom drive machines are more compact, suitable for processing light, fairly soft materials. In this case, the size of the elements can be any.

- Equipment with the motor on top is called rail equipment. Equipped with a motor unit and a disc fixed to the rail. The disc moves along the rail in a horizontal plane. The working surface, on the contrary, remains stationary and rigidly fixed to the frame. Models of this type are professional tools and are capable of producing excellent cut quality. An additional function is the ability to cut not only at a right angle, but also at an angle of 45 degrees. The vertical stroke is 5.6 cm, the cutting length reaches 1430 mm.

Stone cutting equipment

In most cases, these are complex automatic or semi-automatic equipment with high power. They are distinguished by high accuracy of material processing: when two elements are joined, the joint remains practically invisible. Maximum cutting length 1060 mm, depth 420 mm. The engine can be located both above and below. Bottom drive models offer more power and performance.

As an option, a pump can be used to supply coolant to the cutting blade.

The design resembles circular saws, or machines used for woodworking.

Key features to look out for:

- working parameters of the machine, such as power, functionality, the possibility of additional settings;

- the diameter of the disc, on which the depth of cut depends;

- reliability of the fastening system;

- flatness of the working surface, strength and reliability of the guides.

The performance of the equipment will depend on the value of the first two parameters. On the modern market, there are also models of stone-cutting equipment with advanced functionality. For example, the machines of the German company Fubag. In addition to the main task - cutting tiles, models of this brand are used for drilling holes.

Disk selection

For a thin and clean cut, use diamond discs with a thickness of 1.2 - 1.5 mm with a solid edge. Segmented options (with sections cut at the same distance along the outer edge) allow for greater productivity, but do not give an accurate cut. Material heterogeneous in structure with inclusions of pebbles, gravel, reinforcement is processed using "wavy" disks - with uniform diamond segments soldered on both sides, located at an angle to the plane.

When choosing a machine, be guided by such characteristics as power, engine location, saw blade size. Equipment performance, quality, depth and length of cut will depend on these parameters.

Rating of the best stone cutters

This classification will help you choose the right tool so that during work the user can enjoy both the process and the result of his work. First of all, you should pay attention to how much it meets the set requirements.

Household, electric stone cutters

In addition to stone cutters, there are first class installations, the use of which reduces the time for preparatory works for finishing tiles. The ability to control the position of the working parts, the forces applied to the fasteners, and the precise adjustment of the bed increase the accuracy of processing. The correct choice of disc will protect the tile from chipping.

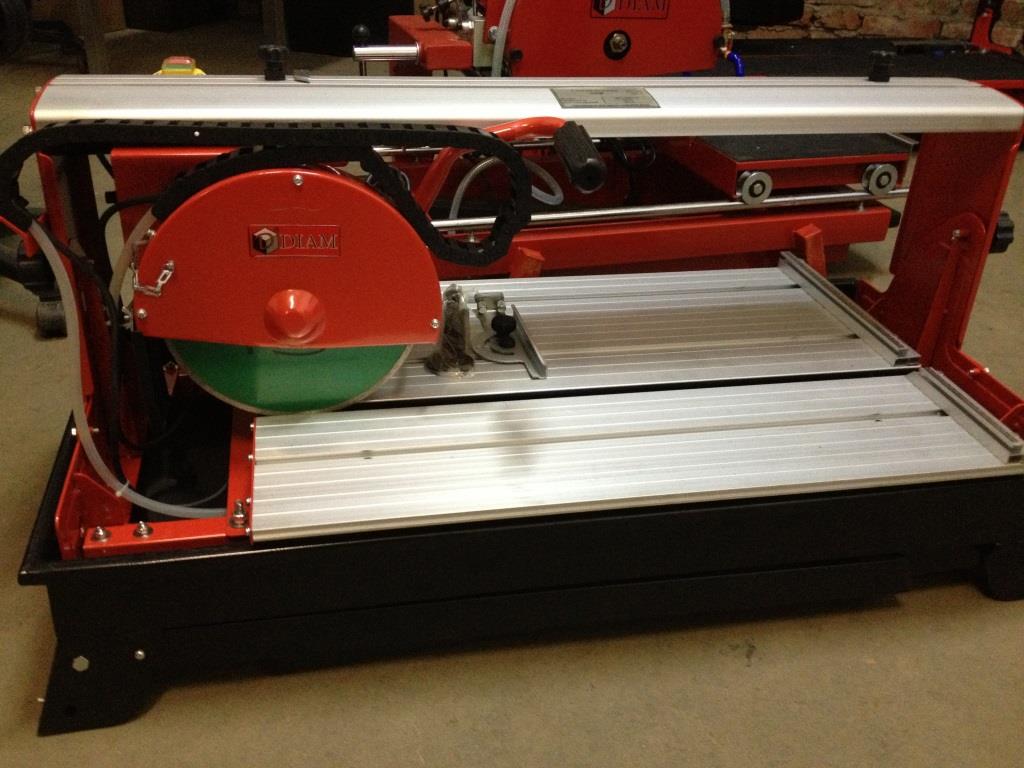

Diam SP-200 / 0.8

The machine mechanism has a significant plus - the cutting part is installed on the main support, the pallet is equipped under the work table. The cutting tool is driven without the use of a clutch and is manually moved along the guide. In this case, in the event of a breakdown, impressive material costs are not needed.

During the production process, there is a rumble and uncontrolled spraying of water. It is possible to put up with such phenomena, provided that the enamel on the tiles will not be chipped during cutting. To obtain the degree of suitability that meets the requirements of the consumer, it is enough to clean the screw thread of the landing axle from burrs, it is better to tighten the nuts, and change the factory carrier to a more impressive version.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 30/21 |

| Cutting length (max), mm | 500 |

| disk diameter (outer / inner), mm | 200/25.4 |

| Disk rotation speed, rpm | 3000 |

| power, kWt | 0.8 |

| Weight, kg | 32 |

Cost: from 13 900 rubles.

- cutting part on the main support;

- the pallet is equipped under the work table.

- roar and uncontrolled spraying of water.

Hammer Plr 900

The best option for arranging the bed is a table, because the length of the legs is not enough for comfortable work. The mechanism is monolithic, but not stubborn - during operation, when feeding the tiles to the carrier, you have to move the bed over the surface. Therefore, the table must be covered with a non-slip and water-repellent cloth. Hammer Plr 900 stands on its legs more securely than on a table. During assembly, check the fastening of all connections and assemblies. An old segmented disc will do, instead of a new solid diamond disc. Working on such a machine is a pleasure.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 36/29 |

| Cutting length (max), mm | 630 |

| disk diameter (outer / inner), mm | 230/25.4 |

| Disk rotation speed, rpm | 3000 |

| power, kWt | 0.8 |

| Weight, kg | 29.3 |

Cost: from 14,900 rubles.

- monolithic mechanism;

- ease of use.

- not found.

Professional stone cutting machines

For such mechanisms, the cutting accuracy for facing material made of porcelain stoneware is + 0.5 mm, that is, it does not exceed the permissible deviations. Under load, the engine power makes it possible to hold from 2800 to 3000 rpm. Thanks to such indicators, highly professional machines practically differ from household ones. In addition, after cutting, there is no need to sand the edges and finish the surface too much.

All samples of this series can process any stone, and the user's capabilities are limited only by the size of the working surface. Almost all cutting mechanisms are produced in several copies, and machines of the same design can be selected for one-, two- and three-phase networks. Manufacturers do not complete their equipment with a dusty disc, because the user selects it in accordance with his requests. Some samples also come without a power cable.

Elitech CK 350 / 90Р

This machine consumes a lot of water. Such a nuance as energetic water supply does not bother the consumer at all, because the working tool leaves the cutting line. There is no clearance on the axle, which causes inconvenience in work. During a thorough examination, it turned out that the retainer was not tightened to the stop. That is why it is necessary to adjust the equipment during operation.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 90/60 |

| Cutting length (max), mm | 600 |

| disk diameter (outer / inner), mm | 350/25.4 |

| Disk rotation speed, rpm | 2800 |

| power, kWt | 2 |

| Weight, kg | 82 |

Price: from 41,142 rubles.

- relatively inexpensive cost.

- there are malfunctions;

- high water consumption.

Helmut ST 350-800

The working mechanism in the equipment of German production. The tongue-and-groove on the edges of the bracket is limited to two pre-positioned positions. To fix any of them, you need to easily tighten the nut. And if you replace the factory fixing nut with an extended one, the setup time is reduced by 2 times.

There are no additional clamps, the burrs of the bracket are held by the base. When installing the working tool in the neutral position, one should not lose sight of the fact that the gate has a long rod, and the structure does not have retaining dowels. If you tighten the nut a little, there is a risk of ripping the thread.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 100/70 |

| Cutting length (max), mm | 800 |

| disk diameter (outer / inner), mm | 350/25.4 |

| Disk rotation speed, rpm | 2800 |

| power, kWt | 2.2 |

| Weight, kg | 75 |

Price: from 46 066 rub.

- German quality;

- easy to work with.

- long tuning.

HUSQVARNA TS 300E

The construction is stable, the tools are fixed rigidly. The carriage moves evenly, is equipped with an anti-slip coating, so there is no need to hold tightly the tiles being cut. The factory-made sludge catcher does not perform its function well - microparticles are drained into the main tank from the sump simultaneously with the liquid.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 100/70 |

| Cutting length (max), mm | 695 |

| disk diameter (outer / inner), mm | 350 |

| Disk rotation speed, rpm | 2800 |

| power, kWt | 2.2 |

| Weight, kg | 82 |

Price: from 54 900 rubles.

- anti-slip coating;

- ease of use.

- malfunctions, adjustment is often required.

CGW 1-25-1 Compact

The bed, installed without props, is quite stable. It is lightweight. The aluminum legs have a small gap in the landing points. When working with lightweight porcelain stoneware, the supports ensure reliable fastening of the structure in the required position. The structure swings from side to side when the curb is being processed on it. But there were no complaints about the clarity of the cut and organizational issues.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 110/75 |

| Cutting length (max), mm | 500 |

| disk diameter (outer / inner), mm | 350 |

| Disk rotation speed, rpm | 2800 |

| power, kWt | 2.2 |

| Weight, kg | 66 |

Price: from 63 800 rubles.

- reliable fastening of the structure;

- stable;

- light weight;

- clarity of the cut.

- not found.

Fubag A - 44/420 M

The tilt of the legs protects the machine from the possibility of the structure tipping over on the long side. To cut a granite countertop longitudinally, it is necessary to remove the mudguard to install additional individual supports, as well as the help of several people. A massive 1500 x 600 x 30 slab may compromise the stability of the equipment. The cleanliness of the cut indicates the absence of beats on the cutting head of the machine. A slight modification of the device and carriage will allow you to do the work yourself without anyone's help. This is evidenced by the declared properties of the model, indicating a large power reserve.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900), mm | 145 |

| Cutting length (max), mm | 590 |

| disk diameter (outer / inner), mm | 420 |

| power, kWt | 2.2 |

| Weight, kg | 72 |

Cost: from 78,300 rubles.

- large power reserve;

- cleanliness of the cut;

- no beats on the cutting head of the machine.

- sometimes several people need help.

Battipav expert 400

The presented models belonging to this series are quite mobile, but it is not very convenient to move them, and then install, put into working position, alone. The racks cannot be adjusted in height, which is invisible when assembling materials for cladding, but at the same time, such a defect will bring discomfort when working on an uneven surface.

The efficiency of the design has no complaints. The innovation in the placement of the sprayer that supplies water to the disc, which is the focus of the manufacturers, when checked in detail did not particularly please the users. A positive quality in the device is the presence of a cut with a laser pointer, thanks to which you can fix the workpiece in a short time, which is very convenient, especially when trimming tile products. Working with blocks, you can do without using it; a readable meter will serve as a replacement.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900), mm | 135 |

| Cutting length (max), mm | 800 |

| disk diameter (outer / inner), mm | 400/25.4 |

| Disk rotation speed, rpm | 2800 |

| power, kWt | 2.8 |

| Weight, kg | 68 |

Cost: from 124,990 rubles.

- the presence of a cut with a laser pointer;

- readable meter.

- not found.

Rubi Dx - 250 1400

The vertical sawing function advertised by manufacturers is a profitable advertising ploy. Correct installation and configuration of cheap prof. units will allow you to ideally perform a geometric cut. The clear advantage is its light weight and removable wheels to easily move it to the desired location, but the length of the frame will require installation on a perfectly smooth surface. Using a full stock of oversized machines with adjustments and cutting corners is more suitable for large scale production.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 145/70 |

| Cutting length (max), mm | 1520 |

| disk diameter (outer / inner), mm | 250/25.4 |

| Disk rotation speed, rpm | 2800 |

| power, kWt | 2.75 |

| Weight, kg | 89.5 |

Cost from 171,500 rubles.

- quick setup;

- small weight;

- removable wheels.

- not found.

Production stone cutting machines

Among the main features of the devices of the presented type is the error-free processing and perpendicular cut of various stones at the desired angle. Trim inaccuracy is considered zero because it is a hundredth of a millimeter. Exceptional cutting accuracy is essential because no gaps are allowed when cutting slabs.

Maneuverable prof. machines differ from shop models in the thickness of the sawn seam. The scale of the cut made on the workshop machines will be slightly larger. The fixed equipment installed in the workshops allows you to quickly and efficiently dissolve slabs from granite, marble, as well as massive blocks and slabs for workpieces.This option is well suited for workshops that process blocks from natural materials for the further production of commemorative plates, kitchen countertops, window sills and steps.

Sima Venus 200 Mekano

The weak point of this model is the support, covering the table with a powerful granite layer having a thickness of 100 mm, most often they do not withstand heavy loads and fit together. The machines are perfect for working with standard posts no more than 50 mm thick, making interior elements and blanks for future worktops.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 100 |

| Cutting length (max), mm | 1500 |

| disk diameter (outer / inner), mm | 300/25.4 |

| power, kWt | 3 (380) |

| Weight, kg | 112.7 |

Cost: from 211 150 rubles.

- well suited for working with granite;

- fast machine setup.

- weak supports.

Nuova Mondial Mec Manta LX TB 120 - 750 Monofase

The declared characteristics of power and cutting depth are not combined with a shortened table, moreover, the machine does not provide for cutting at an angle of 45 degrees. On the whole, the apparatus is powerful, reliable and stable. The series of this equipment released by the Italians in terms of performance and technical characteristics speaks of the creation of a successful model for specific purposes and operation under certain conditions.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900), mm | 300 |

| Cutting length (max), mm | 700 |

| disk diameter (outer), mm | 750 |

| Disk rotation speed, rpm | 900 |

| power, kWt | 2.6 |

| Weight, kg | 190 |

Cost: from 264,200 rubles.

- sustainability;

- good power.

- power and depth do not match the table.

Emmedue ES - 300 A

An electric drive is responsible for the rotation of the cutting parts, which works thanks to manual control. The advantage is the presence of quick-release expanders on the side of the machine and easily rotating shafts. They can be used to cut large natural stones. A small disadvantage of the car is the impossibility of auto-steering.

| SPECIFICATIONS | VALUE |

|---|---|

| Cutting depth (max 900/450), mm | 125/90 |

| Cutting length (max), mm | 3000 |

| disk diameter (outer / inner), mm | 400/30 |

| Disk rotation speed, rpm | 2800 |

| power, kWt | 5.5 (380) |

| Weight, kg | 370 |

Cost: from 756,000 rubles.

- quick-detachable expanders;

- easily rotating shafts.

- no auto steering.

Summing up: which is better to choose

To carry out repair and construction work in your room, you can get by with an inexpensive machine model. It is worth practicing on your own with replacing the base disk and trying the adjustment work. Hand tools are inferior in comparison with models of all machine tools.

Affordable price category Hammer Plr 900 with a minimum amount of dust and a neat cut will make you think about purchasing it.

You should not ignore the purchase of a lightweight machine CG 1 - 25 Compact with advantageous functions, a low weight of about 70 kg, a high accuracy in mm, a disc included in the kit, allowing the processing of the required materials.

To ensure the continuous operation of a compact workshop, the Emmedue Es - 300 machine is perfect, having the potential and capabilities that bring success in production. It meets and complies with all the described characteristics and requests required when performing work at industrial enterprises. When opening a repair shop, the equipment can cover costs and increase the profitability of the enterprise.

Which stone cutter to choose - this question can only be answered by the buyer himself, based on the functions planned to be assigned to the device.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive drugs for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296