Rating of the best gas and electric cutters in 2020

In the process of construction work, one has to deal with the need to cut materials of special strength, for example, asphalt, reinforced concrete, etc. Indispensable equipment in this case is gas cutters and electric cutters. The article will help you choose the right tool, for the convenience of the reader, it is divided into the corresponding main sections in which you get acquainted with gasoline and electric cutters.

Description of gas cutters

The gas cutter is a self-contained and portable disc cutter equipped with a dedicated, high-speed, sharp-edged blade. It differs from the circular saw, which is designed for processing wood and other similar materials, in the ability to cut hard and tough materials like stone, concrete, metal and more.

All cutters with high power gasoline engines. The torque of these motors is sufficient to drive large disc diameters, which allows for faster cutting and processing of certain materials.

Such construction tools are often used when concrete, brick and other metals need to be cut. Of course, the thickness that can be cut depends on the technical characteristics of the gasoline cutters.

Using this equipment, it is easy to cut any structure, such as brick. In addition, such a unit is indispensable if it is necessary to make a slitting or to make a groove.

But this is not the main advantage. The primary advantage of this device is its autonomy, it can be easily used in any place, without forgetting to fill the gas tank. Despite the rather high price, this construction tool is readily available even in times of economic instability, and today it is very popular, more and more consumers have begun to buy this construction equipment for home use. Such a gasoline cutter does not lag behind in its functionality more expensive models that can reproduce the same functionality. You can talk for hours about the advantages of using this construction tool, so it is best to evaluate all the advantages in practice.

Design features of gas cutters

The gasoline cutter includes:

- Powerful engine. The tool must have enough “strength” to cut hard materials. In addition, the engine must have high reliability and durability because it will face very difficult tasks.

- Cutting disc.As we said, the trimming machine does its job with a belt-driven metal disc. The belt is covered with a robust housing for operator safety and to prevent damage during operation. The disc is also specially shielded to propel material particles so that shadows fall on the operator. Discs can be of different diameters (the most common 350 and 400 mm) and types (abrasive for metal, steel, diamond - for concrete, brick, stone, granite).

- Special air purification system. During operation, the unit can raise a lot of dust, which is dangerous both for a person and for the gas cutter itself, therefore both need special protection. The problem of protecting the operator from the harmful effects of dust is solved by putting on an aspirator, and protecting the engine from harmful particles is possible using a multi-stage air cleaning system. It includes centrifugal cleaning as well as various large area air filters.

- Lever. Since the gasoline cutter is a rather heavy tool, so much attention is paid to balancing and the convenience of the handle position (at a distance approximately equal to the shoulder width).

- Progressive vibration isolation system. The powerful engine at high rpm generates significant vibration, which causes severe discomfort during prolonged operation. Therefore, gasoline cutters are equipped with special shock absorbers and a soft grip coating to dampen vibrations and provide a non-slip grip.

Criteria for choosing a gas cutter

The choice depends on:

- The material that the tool must cut: metal, concrete, or both. Less powerful devices will handle metal with less resistance than concrete or stone. If you need to cut them, select the high power models from 5hp.

- Possibility of turning the protective disc cover. To balance the instrument, the blade is closer to the center with the shroud facing out so you can work close to a wall or other objects.

- Cutting type: wet or dry. Wet cutting has less dust, which means less clogged tool parts. In addition, the cutting disc is cooled efficiently and wear is reduced. With regard to dry cutting, it is better to follow this rule when performing work to protect the blade: 40 seconds of cutting - 15 seconds off.

- Brenda. When choosing a tool, an important criterion is the popularity and popularity of the brand and its reputation, which consists of factors such as quality, durability, reliability, safety, ease of use, availability of spare parts and service.

Rating of the best gas saws in 2020

5 - Husqvarna K 760

The Husqvarna K 760 gasoline cutter is equipped with an engine with improved performance as well as lower fuel consumption and minimal gas emissions. This engine improves cut quality and equipment productivity. The gasoline cutter is equipped with an anti-clogging system, making it suitable for long-term operation without the need for cleaning. The starter is equipped with a spring return system with a bearing. Because of this, it does not need any special maintenance. The model has a bushing that allows you to change discs with a fit of 25.4 or 20 mm.

- Large fuel tank;

- Deep cut.

- High price.

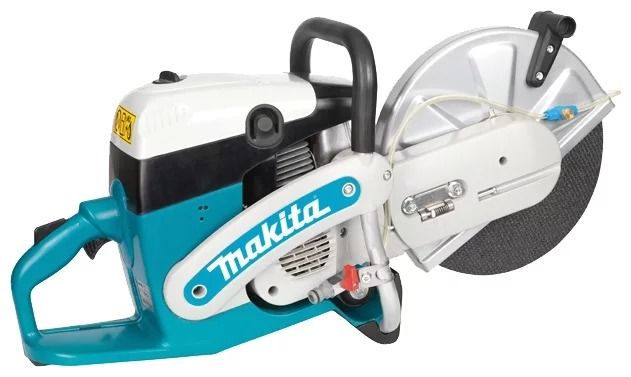

4 - Makita DPC7330

Makita DPC7330 petrol tool with a cutting depth of 122 mm for any material. It can be concrete or stone, asphalt or plaster. Electronic ignition, quick start system, air filtration system. The gas cutter design provides for a 5.6 hp two-stroke engine, a 1.1 liter tank capacity, into which a mixture of gasoline and oil with a 50: 1 ratio is poured. The operating conditions of the unit are associated with a high level of pollution, therefore the engine filtration system consists of five stages. The electronics in the device are also protected from dust and moisture by a highly sealed housing.

- High rotation speed of the disk;

- Low fuel consumption.

- Great vibration.

3 - STIHL TS 420

With the STIHL TS 420, you can easily cut asphalt, building materials from stone, metal, concrete and any natural or artificial hard stone. Due to the fast turning speed of the blade, the saw can easily cut a variety of solid materials with a large thickness. In the semi-professional technical class, this model is the easiest to use. The unit has a compact body, low weight (can be transported and operated with only one hand) and low exhaust emissions. The equipment can withstand such operating conditions as high load, long-term intensive work, cutting of hard materials.

- Wear resistance;

- Wide range of applications.

- Not found.

2 - HUSQVARNA K 770/14 "

The Husqvarna K 770/14 petrol saw is a modern all-rounder with superior performance. An irreplaceable tool during construction and road works, as well as building renovation. Handles bricks, concrete, tiles, metal pipes and other hard materials with ease. Reliable engine quality with easy starting allows you to effectively withstand intense workloads, ensuring stable, efficient and trouble-free operation. In addition, the developers have equipped the device with a special automatic system that guarantees the most acceptable mode of energy transfer, minimizes belt wear and increases its service life.

- Maneuverability;

- Low vibration.

- Fuel tank volume.

1 - Hitachi CM75EBP

The Hitachi CM75EBP gasoline cutter is designed to cut a wide variety of hard materials. This model is equipped with a modern drive with a power of 3.9 kW, which ensures high efficiency, low consumption of gasoline and very little exhaust of gases harmful to humans. Highly durable steel case protects internal components and modules from physical damage. High quality components ensure a long product life. The air filtering device prevents the penetration of dirt and dust, which helps the stator to operate smoothly.

- Large engine displacement;

- Considerable disc diameter.

- Heavy tool.

Characteristics of gas cutters

| Gas cutters | Hitachi CM75EBP | HUSQVARNA K 770/14 '' | STIHL TS 420 | Makita DPC7330 | Husqvarna K 760 Cut-n-Break |

|---|---|---|---|---|---|

| Power | 3900 Wt | 3700 Wt | 3200 Wt | 4200 Wt | 3700 Wt |

| Rotational speed | 4200 rpm | 9000 rpm | 5350 rpm | 4300 rpm | 9000 rpm |

| Engine capacity | 75 cm³ | 73.5 | 66.7 cm³ | 73 cm³ | 73 cm³ |

| Gas tank capacity | 1.1 l | 0.9 l | 0.71 l | 1.1 l | 0.9 l |

| Disc diameter | 350 mm | 350 | 350 mm | 300 mm | 230 mm |

| Fitting diameter | 20 mm | 25.4 | 20 mm | 20 mm | 25.4 or 20 mm |

| Weight | 10.6 kg | 10.2 | 9.6 kg | 9.8 kg | 9.8 kg |

Description of electric cutters

Electric cutters are tools that have high parameters such as quality, practicality, versatility and safety. They are designed for cutting heavier, harder materials. For example, concrete, stone or asphalt. With the sharp blades of the disc, this type of work will be done as efficiently and productively as possible with minimal cost and effort.

Electric cutters are equipped with special deep cutting technology. Thus, modern electric cutters allow you to work at a depth of about 400 mm with low costs during the operation of the tool. Work with this unit can be carried out both inside and outside. Electric cutters are also great for small jobs.

Most electric cutters today come with induction motors. Their power drives are powerful. Therefore, a high speed of rotation of the spindles is created. And the chucks, in turn, rotate the diamond discs with a high torque. With this design, you can cut stones, bricks, cement and other fairly hard materials.

The electric cutter is an environmentally friendly device.This allows you to use the power tool in small rooms with poor air ventilation. An additional advantage is the absence of a strong noise level during the operation of the equipment. The noise that the electric cutter emits during operation is not strong enough, in addition, there will be no unpleasant smell and strong dust during cutting.

Only one power source is needed to use the electric cutter. It is portable and lightweight. The electric cutter has fairly simple instructions and operating guides. Due to the lack of fuel, they do not emit harmful emissions.

Features of the design of electric cutters

Since the cutter is electric, you will need to run electricity in your workplace. The outlet is not always nearby, in such cases diesel generators or the like can be used. It is worth noting that, despite the fact that electric cutters are less powerful than its gasoline counterparts, an irrefutable advantage is the ability to work inside buildings and premises, that is, it is possible to use a construction tool for finishing and other interior work. This equipment is unique for pavement processing - to cut concrete and granite, as well as repair cracks on hard surfaces. It is also great for cutting pipes into trenches.

Electric cutters are indispensable for treating floors, walls or windows. Reducing the coolant supply greatly reduces the risk of failure or blockage of the rotating disc. Different models may have the ability to spray water directly onto the disc. The volume of water is sufficient to eliminate dust and nothing more. Some units are equipped with an anti-vibration system. Thanks to this, the load on the human body is significantly reduced, since electric cutters vibrate very strongly during operation. When determining with the selection of the most suitable equipment, it is necessary to take into account the presence (or absence) of the following modules: overload protection and current limitation systems, changes in rotation speed.

With electric cutters, the protective case is very easy and convenient to open for easy blade change. Most of the models have a bevel gear of the optimal size, which reduces noise level, reduces power losses and ensures high reliability of the electric cutter. The choice of the design of electric cutters also depends on the material with which you have to work: metal, stone or concrete.

Criteria for choosing electric cutters

When choosing a cutter with an electric drive, you need to pay special attention to the main selection criteria:

- The maximum circle diameter used for a particular model. This affects the depth of cut and ease of use.

- Unit power that does not really matter. Equipment of this kind has optimal parameters to work.

- There are models of devices with their own methods of torque transmission. It depends on the composition of the concrete solution. In this case, the model is chosen depending on the preferences of the master.

- On the location of the hand tool: on the body or trolley. At the same time, a concrete electric cutter has various technical characteristics and performs a certain type of work.

In addition to the above requirements, when choosing an electric cutter, additional selection criteria should be considered:

- When buying an electric cutter, you need to take advantage of the offer of additional guarantees, despite the increase in the final cost. With a long and constant use of the power tool, this will be additional insurance, which will be useful help to avoid tangible costs when performing service repairs.

- When buying a tool, you should inquire about the availability of discs and spare parts, wear of parts and their availability.Immediately you need to purchase additional discs and graphite brushes for your electric cutter.

- The specifications written on the packaging may be incorrect.

Rating of the best electric cutters in 2020

5 - Husqvarna K 6500/16 ″ HF

The Husqvarna K 6500/16 ″ HF is equipped with high frequency PRIME technology, which makes the electric cutter the most powerful electric machine. High power output, well-balanced body and low vibration make this cutter very efficient and easy to use. The equipment model allows you to effectively perform any work both inside the house and outside.

- Ease of use;

- Ergonomics.

- High noise level.

4 - Husqvarna K 6500 Ring

The Husqvarna K 6500 Ring is the most powerful ring cutter ever, featuring high power, low vibration technology that makes it incredibly easy to use and suitable for a wide range of jobs. Built-in functions include a safety system that prevents the risk of motor overload. There are additional deep cutting attachments thanks to the peripheral electric cutting system.

- Reliability;

- Good power.

- Large mass.

3 - Husqvarna K 4000 EL 14 ″

The Husqvarna K 4000 EL 14 "is a versatile cutter based on a high power electric motor for dry or wet cutting of hard materials such as concrete, asphalt, tiles and more. The design of the equipment includes various additional and auxiliary functions that ensure the convenience and comfort of using this model.

- Overheating lock;

- Water resistant.

- Brittle plastic.

2 - Husqvarna K 4000 Wet 14 "

The Husqvarna K 4000 Wet 14 "is a powerful, versatile electric cutter with wet and dry cutting set. The unit makes it possible to do smaller cutting jobs indoors with minimal dust generation. Using a wet cutting kit with special nozzles, the double insulated electric cutter provides effective dust suppression. There is an advanced electronic overload blocking system that changes the disc speed when an overload occurs.

- Easy disk change;

- Universal landing sleeve.

- Not found.

1 - Husqvarna K 4000 Cut-n-Break

Universal electric cutter Husqvarna K 4000 Cut-n-Break, the purpose of which is deep cutting of concrete, asphalt, pipes, sidewalks, as well as repair of openings. Used for dry and wet carving. Unlike other electronics, this model rotates forward for efficient cuts with minimal operator input. Thanks to the mains supply, this equipment is considered an ecological model.

- Comfortable handle design;

- Overload protection.

- High price.

Characteristics of electric cutters

| Electric cutters | Husqvarna K 4000 Cut-n-Break | Husqvarna K 4000 Wet 14 " | Husqvarna K 4000 EL 14 " | Husqvarna K 6500 Ring | Husqvarna K 6500/16 "HF |

|---|---|---|---|---|---|

| Power | 2700 Wt | 2700 Wt | 2700 W / 1800 W / 2200 W | 5500 Wt | 5500 Wt |

| Rotational speed | 2700 rpm | 4400 rpm | 3570 rpm | 3000 rpm | 4200 rpm |

| Tension | 230 V | 230 V | 230V / 120V / 110V | 270 in | 220 V |

| Disc diameter | 230 mm | 350 mm | 350 mm | 350 mm | 400 mm |

| Fitting diameter | 25.4 mm | 25.4 mm | 25.4 mm | 25.4 mm | 25.4 mm |

| Weight | 8.9 kg | 8.5 kg | 8.5 kg | 13 Kg | 10 Kg |

The technologies for the production and manufacture of construction tools are constantly being improved. The range of petrol and electric saws is expanding every year, and the quality and reliability are periodically improving. It can be concluded that the future of gasoline and electric cutters is cloudless and secured by supply and demand for these products.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive drugs for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296