Deep vibrators rating for 2020

Deep vibrators are specialized construction equipment designed to compact concrete mortar in the construction of floors, walls, foundations, reinforced concrete and monolithic structures and similar structures. Such a device is needed in order to increase the strength and reliability of structures and buildings. After all, the better the concrete, the longer the structure will stand.

And on an industrial scale, high quality concrete mix is important for the preservation and safety of human life during the construction of structures such as dams, tunnels, bridges and others. Next, we will consider professional and amateur deep vibrators that can be used and used by ordinary people who do not have special knowledge and skills in the construction and manufacture of monolithic and reinforced structures, structures and buildings.

The principle of operation of the deep vibrator

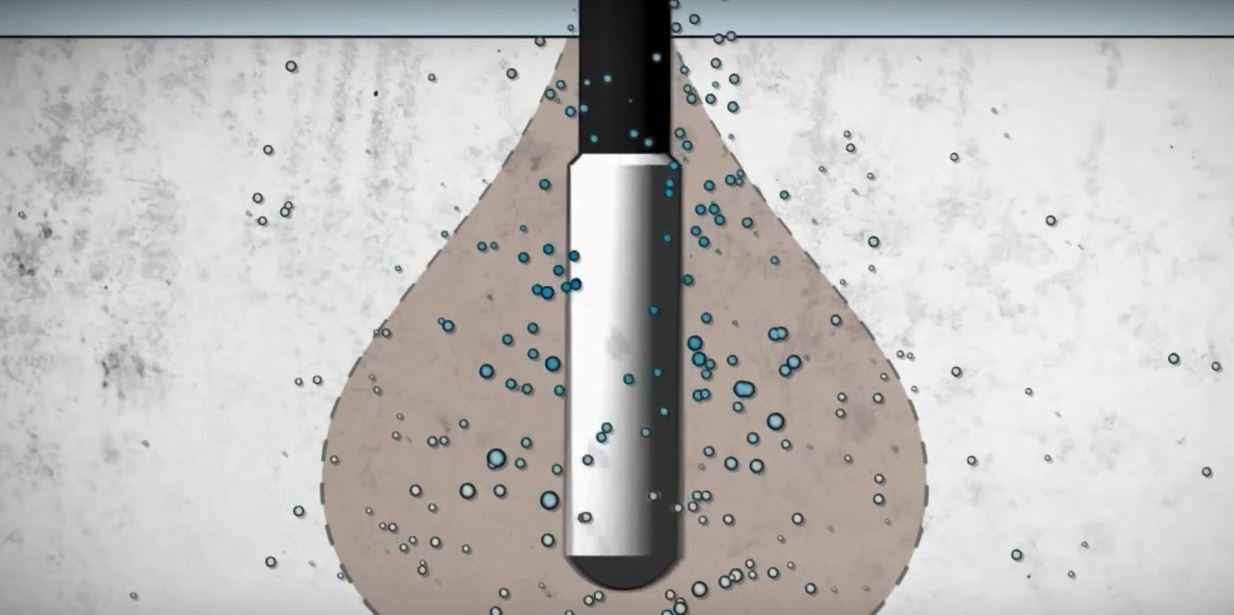

A concrete solution, in essence and in its purpose, is a composition, a homogeneous binder mass based on water, a mixture of sand, crushed stone, cement, consisting of lumps and particles of various sizes. To ensure high quality concrete, it is necessary that its constituent components are tightly connected with each other, and there are no air bubbles and cavities between them, thereby increasing characteristics such as strength and durability.

For the manufacture of such a high-quality concrete solution, such construction equipment as a deep vibrator is used. The device acts on a mushy concrete solution by vibrating waves with vibration, which contributes to the settling of high-density particles and the release of air bubbles. As a result, a homogeneous mass of concrete is obtained without air bags or other defects inside the solution. The use of deep vibrators helps to increase the load-bearing properties of large-scale concrete structures. The unit is intended only for use with thick concrete, ideal for pouring a monolithic foundation or wall formwork. The downhole equipment is equipped with a long or short soft sleeve, which is used to ensure that the surface of the concrete is even during the pouring of walls or foundations, respectively.

Let's consider in more detail what happens during the operation of the equipment. Downhole equipment operation performs the following main functions:

- Sealing solution

The reliability of concrete lies in the uniform distribution of loads throughout the entire volume of the mixture.The vibration properties help the filler to fill the volume of the void to be filled with the same density.

- Air outlet

When a homogeneous mass of concrete vibrates, a pressure arises in the solution, which undoubtedly helps air bubbles break through the concrete to the outside. The fewer empty cavities in concrete, the stronger and more reliable it is.

- Filling cavities

Vibration also helps to fill the voids that have arisen after preparing the container for pouring the solution, which will ensure reliable adhesion to the contacting surface.

Differences between deep vibrators on the power drive

The structure of the deep vibrator can include the following types of drives:

- Diesel;

- Petrol;

- Electric.

Diesel or petrol drives are equipped with engines based on the principle of internal combustion of the respective fuel. The huge advantages of such drives are their autonomy and the ability to work in any environmental conditions. The disadvantage is the regular waste of money on diesel or gasoline fuel. Due to the release of poisonous gases resulting from the combustion of combustible fuel, deep vibrators with diesel or gasoline drives are not recommended for use in closed and unventilated rooms to exclude the possibility of poisoning of workers. If we compare diesel and gasoline equipment, then the vibrator based on diesel fuel is much more powerful and more economical, but more expensive in price.

The electric drive that powers the vibrator is very popular and widespread due to its simplicity and operation. Electric motors from a common 220 V network work directly from the outlet, and 380 V motors - through a transformer that reduces the voltage to 48 V. The disadvantage of such a deep vibrator is the inability to operate the equipment without being connected to the electrical network. Connecting the vibrator to an electricity generator will help solve this problem.

Differences in downhole equipment by vibration method

By the method of vibration, deep-seated units are distinguished into high-frequency, pneumatic or mechanical.

- High frequency vibrator

The power drive of this vibrator is small. The unit is very easy to operate, it has a flexible hose up to 20 meters long. From the name of the vibrator, it is clear that its operation is based on high-frequency vibration, which is obtained using a converter that converts 50 Hz of the general network into 200 Hz. This transducer can be either installed inside the vibrator system or as a separate plug-in module.

Converters as a separate unit are more common due to the convenience of equipment repair. Do not disassemble the sleeve and do not solder the conversion circuit, which is almost impossible to find, unless there is an identical vibrator model, but simply replace the block, which is much easier and safer. Basically, a high-frequency unit with a vibration depth has the ability to connect to several outlets of a common network, which allows you to simultaneously connect up to 6 flexible hoses with vibration tips to it. This design will allow a whole team of builders to process a large amount of concrete solution, which reduces the duration of work and increases labor productivity.

- Pneumatic vibrator

The principle of operation of a pneumatic vibrator is the operation of compressed air, which comes from a compressor. Low-power compressors, such as those for car tires, paint equipment, etc., are not suitable for concrete. The power of a pneumatic vibrator directly depends on the ability of the compressor equipment to maximally compress the air leaving it. The vibrator itself has a low cost than the compressor unit. It is advisable to buy a pneumatic vibrator if you already have a compressor and other pneumatic equipment, such as bolt cutters, jackhammers and others.

- Mechanical vibrator

The most popular type of vibrator with little efficiency. The design includes a power drive, flexible shaft and mace. During rotation, the concrete solution is compacted and distributed into all empty cavities. An electric motor is usually used as a power drive, to which a flexible shaft is connected. The shaft consists of a protective case that ensures human safety during operation of the vibrator, inside which there is a cable, with its help, rotation is carried out.

The vibration club, located at the end of the cable, can be easily removed and replaced with vibration nozzles of other diameters, if necessary, which are included in the delivery set. An important requirement in the operation of a mechanical vibrator is to exclude the possibility of bending the shaft at the point of its connection to the power drive, which will help to avoid overloading the motor. To solve this problem, manufacturers of some models have come up with and included in the package a device for hanging the vibrator on the operator's back.

Downhole equipment selection criteria

In order to choose the right vibrator, you need to take into account how much work you will have to face and what needs to be processed: a beam, a foundation, a slab, and the like. After designating the purpose and direction of work, it is already possible to determine the technical characteristics of the downhole unit, such as the type of drive, engine power, length of the flexible shaft, diameter of the mace, vibration frequency and others.

First you need to decide on the type of power drive. If you have access to the electrical network, then you can choose an electric motor. If not, a fuel-based, diesel or gasoline engine will do.

The power of the power drive is also an important characteristic when choosing a deep vibrator, which is in the range of 400-1500 W. The quality and duration of work depends on it. There are more powerful motors that are used in the construction of large-scale structures.

The length of the soft shaft is up to 12 meters, which depends on the depth of the vibrator.

The choice of the diameter of the vibrating tip depends on the thickness of the concrete layer and is 0.25 of it. In general, the handpieces are supplied in diameters from 28 to 60 mm.

The delivery set must include a product passport, a certificate of conformity, and a warranty card. The price of downhole equipment directly depends on the manufacturer of the product and the technical characteristics of the product, which fluctuates in the range of 5000-7000 rubles, depending on a manual or industrial vibrator.

Rating of the best deep vibrators 2020

The rating is an overview of the most popular and famous models of vibrators for 2020. The list includes both domestic and foreign manufacturers of construction equipment. Additional information in the form of advantages and disadvantages shows the opinions and reviews of buyers and consumers of devices for compacting concrete solutions and mixtures.

Vektor 35H

In tenth place is the downhole equipment Vektor 35H, designed for compacting concrete mortar at a depth that depends on the size of the shaft. The brushless design includes a system to protect the device in the event of malfunctions and faults in the electrical network. The device also includes a dynamic rotor balancing system, which eliminates the possibility of wear at high rotor speeds. The electric motor is securely hidden in the case in order to avoid dust, splashes, water and other things entering it.

- Shaft bending up to 300 mm;

- Rotor balancing system.

- Not found.

Red Beacon EPK-1300

In ninth place is Krasny Mayak EPK-1300 - an electric submersible device, which belongs to the category of professional tools designed for processing concrete mortar for the construction of concrete and reinforced foundations.The design consists of an electric motor, which rotates using a flexible shaft of the vibrotip vibrating at a certain frequency. With the help of vibration, concrete solutions and the mixture are compacted, and air bubbles are also released from them, which rise outward from the total mass, thereby compacting the concrete. The strength of the concrete mortar significantly improves the quality of the foundation itself.

- Very powerful;

- The optimum ratio of price and quality.

- Lack of quick-release connection of the flexible shaft with the drive.

VPK ELECTRON 50

In eighth place is the downhole equipment VPK ELECTRON 50, which includes: a hose, a vibrating tip, an electric motor and a transducer, which is soldered into the device. The device is connected to a general network with a voltage of 220 V and a frequency of 50 Hz. The sleeve is 5 meters long and has double reinforcement. The transducer is safely hidden in an aluminum casing. This model is intended for compaction of concrete mix during the construction of walls and foundations. Concrete processing is carried out with high frequency vibration, which breaks down the lumps of mortar and releases air bubbles and cavities.

- Large centrifugal force;

- High performance.

- High price.

Patriot CV 100

In seventh place is the Patriot CV 100 downhole equipment, which is used in the construction of concrete and reinforced concrete structures and structures. The use of this unit allows ensuring the strength of future buildings by compacting concrete and removing air bubbles and cavities from it. The set with the device includes a flexible shaft, the length of which is 2 meters. An excellent advantage of the vibrator is the heat removal system, which ensures the operation of this device for a rather long time.

- Reliable electric motor;

- Very comfortable D-shaped handle.

- Short length of flexible shaft.

Champion ECV550

In sixth place is the Champion ECV550 deep vibrator, which effectively and reliably compresses concrete mortars in the construction of reinforced concrete and monolithic structures. The electric motor of the downhole unit contributes to high stable operation. The vibration frequency of the vibrator is 183 Hz. The design of the equipment consists of a vibrating tip, a flexible shaft and an electric drive. Flexible shaft length is 4 m. Vibrator head diameters: 28, 32, 38, 45 mm.

- Simple and easy to use;

- Several tips.

- Low vibration frequency.

Vektor-2200

In fifth place is the deep vibrator Vektor-2200. It is used to improve the quality of concrete mortar by vibration in the construction field. The model is equipped with an electric motor and flexible shaft. The splash-proof housing provides a sealed reliable protection of the vibrator from possible moisture. Shaft bending allows access to areas that are difficult to reach due to the nature of the building structure. In order for the equipment to last much longer, it is recommended to operate it for about 6 minutes, followed by a 4 minute rest break.

- Great power;

- Residual current device.

- Shutdown time.

IV-78

In fourth place is the downhole device IV-78, which is designed to compact the concrete mix and remove air bubbles from the solution. There is a frequency converter in the design of the equipment, which is easily adjustable, which is very convenient when pouring concrete. The composition includes a short sleeve and a handle for ease of use. The deep vibrator operates from a voltage of 42V, which is absolutely safe for human life and health. Small dimensions and lightness provide simplicity and ease of operation of the unit. A feature of the vibrator design is that the engine of the unit is located inside the vibrotip, therefore the equipment has a very long service life than other deep vibrators.

- High power;

- Small size and weight.

- Not found.

IB-75 / 3m

In third place is the downhole equipment of the classic design IB-75 / 3m, which is designed to process and improve the quality of concrete solutions and mixtures. This unit operates from a 42 V transformer, the voltage of which is safe for human life and health. The vibrator model is widespread and versatile for performing and solving a variety of construction tasks. The transformer power must be no more than 3 kW. The scope of delivery may include either a single tip or several types of vibrator heads.

- High power;

- Great performance.

- Great weight.

IVNR-44

In second place is the downhole equipment IVNR-44, which is a pneumatic vibrator, which is supplied without flexible hoses. The unit begins to function with the supply of compressed air coming from the compressor equipment. A big advantage is the vibrator's immunity to air pollution. The design of the unit provides for the use of pressure inlet and non-pressure outlet hoses that are connected to the vibrator head. Moreover, the inlet sleeve is located inside the outlet. It has high power and, thanks to its design, durability.

- Frequency adjustment;

- Optimal cost.

- Compulsory use of a compressor.

STEM Techno SWE 1000

In the first place, the high power, mains powered STEM Techno SWE 1000 submersible vibrator is an excellent equipment for compacting concrete slurry. Thanks to the electric drive, it provides high quality concrete mix. With its high vibration frequency, this model is widely used in construction sites and foundations. The equipment generates with its high frequency 5000 rpm and perfectly removes air pockets from the concrete mortar. The operation of a deep vibrator does not require special knowledge and skills, therefore it does not cause problems in its use and application.

- Great power;

- Frequency adjustment.

- Availability of electricity.

conclusions

From the review and rating it can be seen that deep vibrators are widely popular and famous among the citizens of our country in 2020. The list includes both Russian and foreign manufacturers of construction equipment and tools. The variety of the product range allows you to find the most suitable device in terms of cost and purpose to ensure high-quality and reliable construction of various concrete and reinforced concrete structures and structures.

The high quality of downhole equipment makes it possible to perform long-term work of compacting concrete masses much faster, more reliable and more profitable. The resulting concrete structures after processing with deep vibrators are highly durable, which is a very important characteristic of the inviolability during the construction of any facility.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive medicines for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87680 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best in 2020 means for male potency with a description

Views: 68296