Best Plasma Cutters in 2020

It has long been known that the most common metal cutting tools are acetylene torches. Many construction workshops and various enterprises use this method. However, there is an easier and more convenient way to cut with a plasma cutter. Such a tool can easily boast of compactness, cutting speed and high flame temperatures, which in action will provide processing of even the most durable metals.

Brief information

Plasma cutting device operates due to ionized gas, which is heated up to 30 thousand degrees during processing. With this high temperature, metal products up to 50 millimeters thick can be cut with ease. The gas that subsequently undergoes the ionization process can be:

- Nitrogen;

- Water vapor;

- Air;

- Carbon dioxide;

- Argon.

Fubag plasma 40 air

This tool offers the most common cutting method thanks to its built-in compressor.

The cutter offers fairly fast processing of carbon and stainless steel, various aluminum alloys, etc.

The complete set of the device includes a copper grounding cable 4 meters long, a protective cap and a plasma torch.

- Built-in Air compressor, which provides the mobility of the plasma cutter;

- High-quality metal cutting;

- Contactless arc striking;

- Accidental overvoltage protection system.

- Small cutting thickness.

Specifications

| Parameters | Specifications |

|---|---|

| Mains voltage | 220 V |

| Cutting current | 20-40 A |

| Cutting thickness | 15 mm |

| Load power | 5 kW |

| Dimensions | 525x220x405 |

| Weight | 19 kg |

| Consumed electricity | 16 A |

| Network frequency | 50 Hz |

| Standard cutting thickness | 8 mm |

| Price | 76,000 rubles |

Grovers CUT 60

Improved plasma apparatus Grovers CUT 60 is an indispensable device in any enterprise, which will carry out work on the dismantling of metal structures from stainless and carbon steels, aluminum and similar metal alloys. The cutter has a 95% duty cycle and the steel cut is 25 millimeters thick.

It is quite easy and convenient to work with this tool. This is facilitated by its compactness, relatively low weight, as well as a central adapter and a pressure gauge installed in the housing. These parts provide high-quality cutting of metal materials and materials with painted surfaces.

- Ease and ease of use;

- Fast cutting of steels, various alloys and non-ferrous metals;

- Installed protection ip23, which contributes to safe work with the tool outdoors in high humidity or in the rain;

- Independent protection system;

- Complete absence of interference for sensitive equipment during non-contact arc ignition.

- Short network cable.

Specifications

| Parameters | Specifications |

|---|---|

| Mains voltage | 220 V |

| Cutting current | 10 - 50 A |

| Cutting thickness | 15 mm |

| Stroke voltage | 360 in |

| Power | 7.9kw |

| Dimensions | 590x245x435 |

| Weight | 23 kg |

| Pressure | 7.1 bar |

| Network frequency | 60 Hz |

| Display | Present |

| Network cable | 2.5 m |

| Price | 76,000 rubles |

Foxweld plasma 43

The next device is considered a prominent representative of a multifunctional device, which includes three areas at once:

- Manual arc welding;

- Argon-arc DC installation;

- Plasma cutting device.

This device is considered an excellent option for small workshops, where minimal costs for such a tool are required.

During manual arc welding, the device sets a stable welding current, thanks to which it will be possible to work with any type of electrodes.

The argon-arc welding mode boasts an installed oscillator, with the help of which non-contact arc ignition is performed.

Plasma cutting mode has wide functionality. During operation, it is possible to cut high carbon steels, stainless steels, aluminum and copper alloys, as well as alloys from many non-ferrous metals. This installation usually has two main components: a torch and a power supply. The cutter, another name for which is the plasmatron, is considered the main working part of the system. The main task of the torch is to ignite the arc and further ensure the transformation of the passing air into a plasma jet, the concentration and stabilization of this jet, which subsequently will achieve the best accuracy, as well as speed when cutting metal.

Basically, the plasma gas is air, which comes from the compressor and the pneumatic network. For cutting non-ferrous metals, it is best to use nitrogen.

Despite its wide functionality, this device boasts really small dimensions, lightness, and also reduced power consumption from a regular network. Its maximum cutting thickness is:

- 11 millimeters for steel;

- 10 millimeters for welding.

Each mode for processing and cutting materials includes a corresponding row of cables and other components.

- Lightness and compactness;

- Wide functionality;

- Reduced energy consumption and ergonomics;

- Low cost.

- Relatively small metal cutting thickness.

Specifications

| Parameters | Specifications |

|---|---|

| Voltage | 220 V |

| Cutting current | 20-40 A |

| Cutting power | 11 mm |

| Load power | 6 kW |

| Protection class | IP21s |

| Dimensions | 425x200x250 |

| Weight | 14 kg |

| Insulation class | F |

| Price | 24,000 rubles |

Aurora Pro airforce 100

The Aurora Pro airforce 100 plasma cutter is considered one of the most sought-after and powerful of its kind. Individual control circuit, non-contact ignition of the arc, current in the amount of 100 amperes give a unique opportunity for fast and high-quality cutting of metal structures up to 40 millimeters thick. This unique cutting device has noticeable mobility, an excellent cooling system, a fairly small footprint, a user-friendly control panel, and also impresses with its decent performance in the process. The duty cycle is 60 percent when using 100 A and also has an efficiency of 80%. The built-in stabilization system and 380 V mains supply make it possible to use the unit taking into account unstable networks. The available inverter is excellent for cutting high carbon and stainless steels, various ferrous and non-ferrous alloys.

The Aurora Pro airforce 100 is powered by powerful and reliable igbt transistor modules. It is also worth noting that such transistors operate on the principle of pulse-width modulation. This indicates that reinforced power transformers with small dimensions and weight category can be used in the inverter.Given these data, it can be said that the cutting device has excellent technical performance, remarkable performance, reliable operation and small size. Pulse width modulation in collaboration with igbt transistors was able to increase efficiency up to 80 percent.

When machining metal products, the Aurora Pro airforce 100 delivers surprisingly high cutting quality with the required edge standards, and there is absolutely no warping on metal surfaces. This effect was achieved due to the non-contact ignition of the arc, high stable set parameters, as well as continuous air supply. With this in mind, the machining technician can have complete control over the cutting process, from arc fire to extinction. This stroke provides decent performance and significantly reduces the time required for edgebanding.

In order to ignite the torch in the device, you just need to bring the cutting part of the device to the surface of the metal structure at a distance of within 1 millimeter and push the button on the cutter. As a consequence, contactless ignition of the torch will occur and the process of processing or cutting will follow. It is worth considering that in the process there is absolutely no sticking of the tip of the cutting tool and the surface of the metal structure. During processing, material warpage or any similar defects are not detected. In addition to all of the above, contactless ignition of the arc quite quickly reduces the wear of consumables, and also makes it possible to cut metal materials taking into account the holes without stopping.

Taking into account the maximum operating current of one hundred amperes, this plasma cutting device is capable of producing a cut of metal structures with a thickness of more than 40 millimeters. Taking this into account, the PV will not fall less than 65 percent, and such a stroke makes it possible to process for a rather long time with high intensity. If you cut products with a thickness of 20-30 millimeters, then the PV can jump up to 100%. With this capability, you can completely eliminate unwanted downtime during your workflow. This will promote complete concentration during the task at hand and will help to complete it as quickly and efficiently as possible.

The Aurora Pro airforce 100 has a decent cooling system that will maintain the required operating temperature even during intensive use. The cutting tool is easy to adjust with a single adjuster located on the front of the body. There is also a digital interface. If during the working process there is an overload of current, overheating or other unexpected phenomena, then a special protection will immediately work, which instantly turns off the entire system of the device. This will be signaled by the indicator lights located on the front of the case.

Connectors for connecting the cutting part, ignition and mass are located in the lower part of the body. To connect the compressed air supply, pay attention to the rear area of the machine. For this, the necessary fitting is located there, as well as a three-pole automatic device. Stable and continuous operation of the plasma cutter is ensured by a stable working pressure, which should not exceed 5 atmospheres. Several special handles are built into the body of the device, as well as a trolley with wheels, which will facilitate easy and maneuverable transportation of the device.

- The ability to cut metal 40 mm thick;

- Built-in transistors of the latest generation;

- Contactless arc ignition;

- Supports pulse width modulation;

- Superior cutting quality;

- Maintaining protection against electric shock and overheating;

- Mobility and ease of use;

- The absence of any defects on the treated surface.

- High price.

Specifications

| Parameters | Specifications |

|---|---|

| Mains voltage | 380 V |

| Cutting current | 100 A |

| Cutting thickness | 40-45 mm |

| Power | 19 kWt |

| Temperature | 50 degrees |

| Dimensions | 550x290x550 |

| Weight | 43kg |

| Pressure | 5 bar |

| Current consumption | 24 A |

| Length of cable | 6 m |

| Reducer | 1 PC. |

| Price | RUB 95,000 |

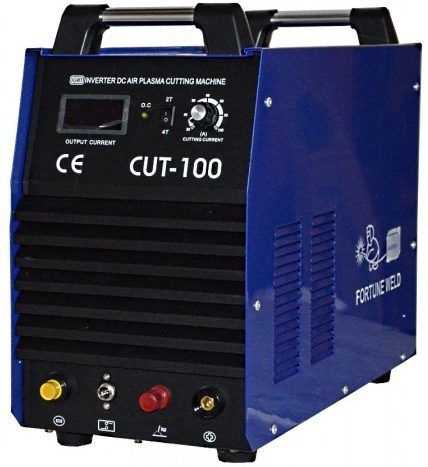

Svarog CUT 100

The next representative of the plasma cutting tool is also considered a worthy device and works on updated transistors from Siemens. Considering the wide range of working electricity 20 - 100 A, as well as the increased compressed air pressure of at least 0.6 MPa, the device can easily cut metal structures with a thickness of more than 35 millimeters. The improved 2t-4t operating mode and high frequency arc fire bring high performance and efficiency of the inverter during the working process, taking into account any conditions. Safety during operation with the device is provided by special protection against electric shock, a sensor for controlling the air supply, a toggle switch for low inlet pressure. Thanks to this range of possibilities, you can easily and conveniently cut various alloys of ferrous and non-ferrous metals.

The body and hardware of the device are equipped with second-generation transistors from the German company Siemens. The control system of the apparatus is considered digital and operates on the basis of the atmel Dsp chipset. Thanks to such a powerful system, the plasma cutter can consistently deliver an efficiency of at least 90%. It also has a power factor of at least 0.8 and a duty cycle of 60 percent. An electronic control unit is integrated into the housing, which, together with the latest inverter technology, adheres to the specified cutting parameters during the entire work process.

The working process of the Svarog apparatus should be carried out with the necessary supply of sufficient compressed air with an initial pressure of 0.6 MPa and a further feed rate of 255 liters per minute. The design has an oscillator that allows you to quickly ignite the arc, taking into account absolutely any conditions, with just one press of a special key. Considering this fact, the brisk arc inflow, which is compressed by a high pressure indicator, heats up to high temperatures within 15 thousand degrees, thereby turning into a plasma torch. The established cutting conditions make it possible for the most effective work with the device during short-cycle and long-term processes. Based on the adjusted concentration of the heat flux, the cutting barrel can make a cut, both at sharp and obtuse angles (5-10 degrees).

This cutting method is often used when dismantling or erecting complex metal structures with a large number of protruding edges. In addition to these possibilities, there is also a shape cutting mode that can be performed in the interior of a metal material. The available working electrical cutting range of 100 A and the most powerful plasma arc with a high temperature allow cutting many low and high carbon steels, alloy steels, aluminum and copper alloys, as well as non-ferrous metals, the thickness of which can reach 35 mm and more. After arc treatment, a wonderful cutting seam is formed, which does not require further plumbing work.

In addition to compressed air, for high-quality cutting, it is worth connecting a three-phase 380V network to the unit. The set contains an electronic unit that stabilizes possible power surges. For safe operation, a special overload protection is located in the design of the device, which automatically works and turns off the system as a result of strong surges in the electrical network.

The Svarog plasma device has a digital display on the front panel, thanks to which you can easily set the working electricity indicator required for operation in the range from 20 to 100 Amperes. There is also a special regulator for selecting the 2t and 4t modes, as well as a gas testing regulator, which provides free access to the main functions of the device inverter.The existing overload protection system and rather powerful fan blades ensure uninterrupted operation of the device even during intensive work under the highest loads.

The body of the device structure contains several air vents, which facilitate the rapid release of hot air. The body itself is made of durable steel, which is not subject to mechanical damage, and the presence of a number of comfortable handles and eyebolts contributes to the convenient movement of the unit. It is definitely worth remembering that the presence of plasma technology provides maximum safety for the cutting specialist, because the presence of any flammable substances is not required at all.

- Availability of modes 2t - 4t;

- High temperature plasma torch;

- The thickness of the metal cut is from 35 millimeters;

- Display for setting cutting modes;

- Gas testing function;

- Overheating and system overload protection;

- Upgraded cooling system.

- The high cost of the device.

Specifications

| Parameters | Specifications |

|---|---|

| Mains voltage | 380 V |

| Cutting current | 20 - 100 A |

| Cutting thickness | 35 mm and more |

| Stroke voltage | 350 in |

| Efficiency | 85% and above |

| Power | 20 kWt |

| Dimensions | 610x330x580 |

| Weight | 47 kg |

| Pressure | 6 bar |

| Network frequency | 50 Hz |

| Insulation class | F |

| Price | 123,000 rubles |

Linkoln electric Tomahawk 1538

This machine is easily suitable for cutting various metal products from ferrous and non-ferrous alloys, high carbon and alloy steels. With the carbon electrode, it became possible for air arc gouging.

The unit, as a rule, must be connected to a 220 V network. It fully supports all Russian and European standards, and the manufacturer provides a warranty for the device for a period of 36 months.

A distinctive feature of this model is the creation of a powerful narrowly directed plasma vortex. With minimal heating of the metal product and the complete absence of any deformations, it is possible to avoid further locksmith surface treatments.

- Excellent cutting quality;

- Long-term cutting nozzle service;

- The latest torch ignition method;

- Excellent air cooling system.

- The cost of the device is too high;

- Large dimensions of the device.

Specifications

| Parameters | Specifications |

|---|---|

| Mains voltage | 380 V |

| Cutting current | 100 A |

| Dimensions | 460x300x650 |

| Weight | 36 kg |

| Price | 140,000 rubles |

The modern arsenal of plasma cutters has an impressive list of representatives, both in the price segment and in technical characteristics. In this article, a detailed analysis of the available devices was provided, which are suitable for both small assembly shops and for serious enterprises.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive medicines for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87680 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best in 2020 means for male potency with a description

Views: 68296